What is Inventory Turnover?

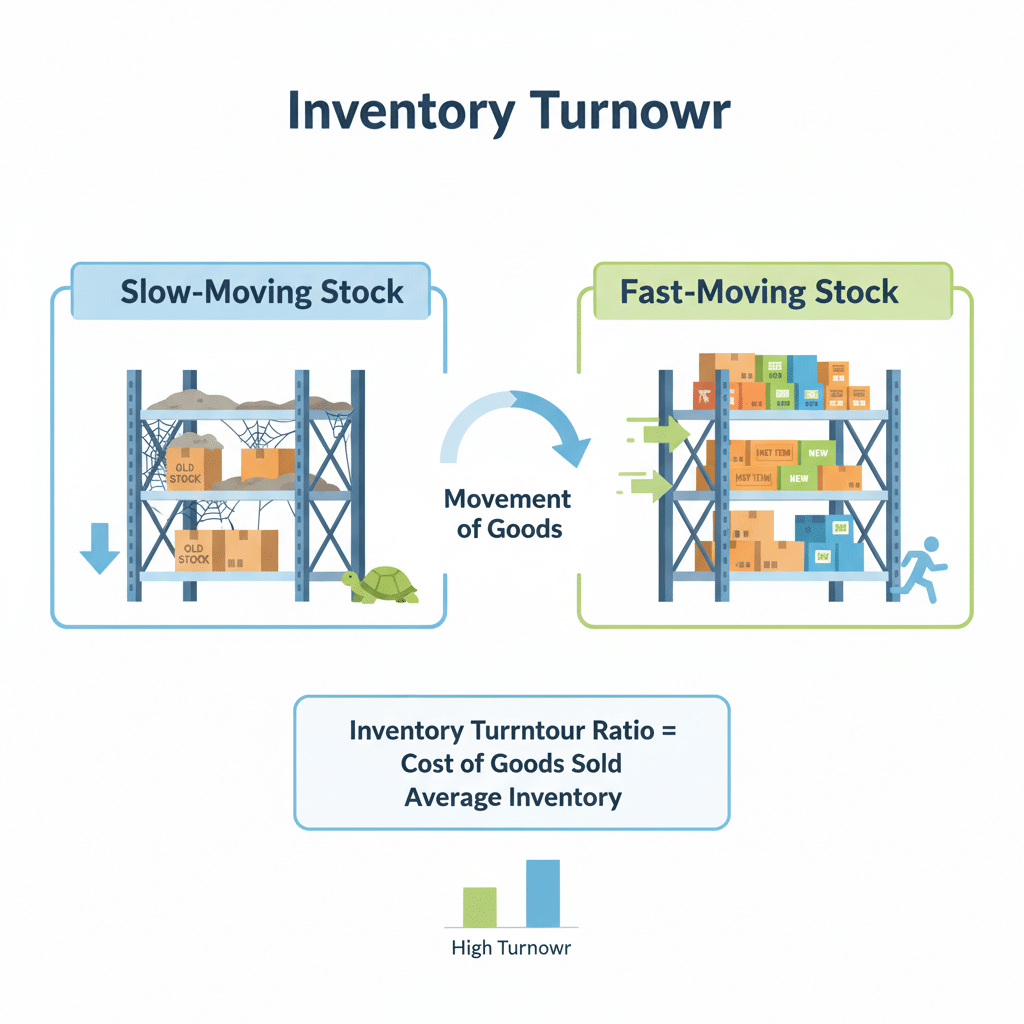

Inventory turnover is a metric that shows how often a company sells and replaces its physical products during a given period. It tells you whether your inventory moves quickly or slowly. Therefore, businesses use it to make smarter decisions about pricing, purchasing, and production.

Why Inventory Turnover Matters

Slow-moving inventory ties up capital and raises storage costs. In contrast, fast turnover improves cash flow and reduces the risk of obsolescence. Additionally, industries like fashion and perishables need high turnover because products quickly lose value.

How to Calculate the Inventory Turnover Ratio

Use the formula below to measure your turnover:

- Inventory Turnover Ratio = Cost of Goods Sold ÷ Average Inventory

To compute average inventory, add the inventory at the start of the period to the inventory at the end, then divide by two. For example, if your beginning inventory is $3,000 and your ending inventory is $5,000, the average is $4,000. If your cost of goods sold is $12,000 for that period, your turnover ratio is 12,000 ÷ 4,000 = 3.

What’s a “Good” Turnover Ratio?

What counts as good depends heavily on your industry and product type. For example, grocery stores often achieve high turnover because items perish quickly. Meanwhile, retailers of furniture or high-end electronics may have lower ratios but earn higher margins per sale. Always compare your ratio to industry benchmarks.

Common Pitfalls & How to Avoid Them

- A high turnover ratio may cause frequent stockouts, which frustrate customers. To avoid that, maintain safety stock or streamline replenishment.

- A low ratio might mean over-stocking or poor demand forecasting; consider promotions or markdowns to clear excess inventory.

- Misreporting inventory values (for instance, failing to include freight-in or ignoring obsolescence) may distort your numbers. Ensure all costs and adjustments are included in your calculations.

How to Improve Inventory Turnover

- Forecast demand more accurately using sales history and market trends.

- Use promotions or discounts to move slow-selling items.

- Optimize purchasing schedules so you don’t overbuy.

- Implement an inventory management system that tracks movement and alerts you when items are idle.

- Review product assortment regularly and discontinue items that consistently underperform.