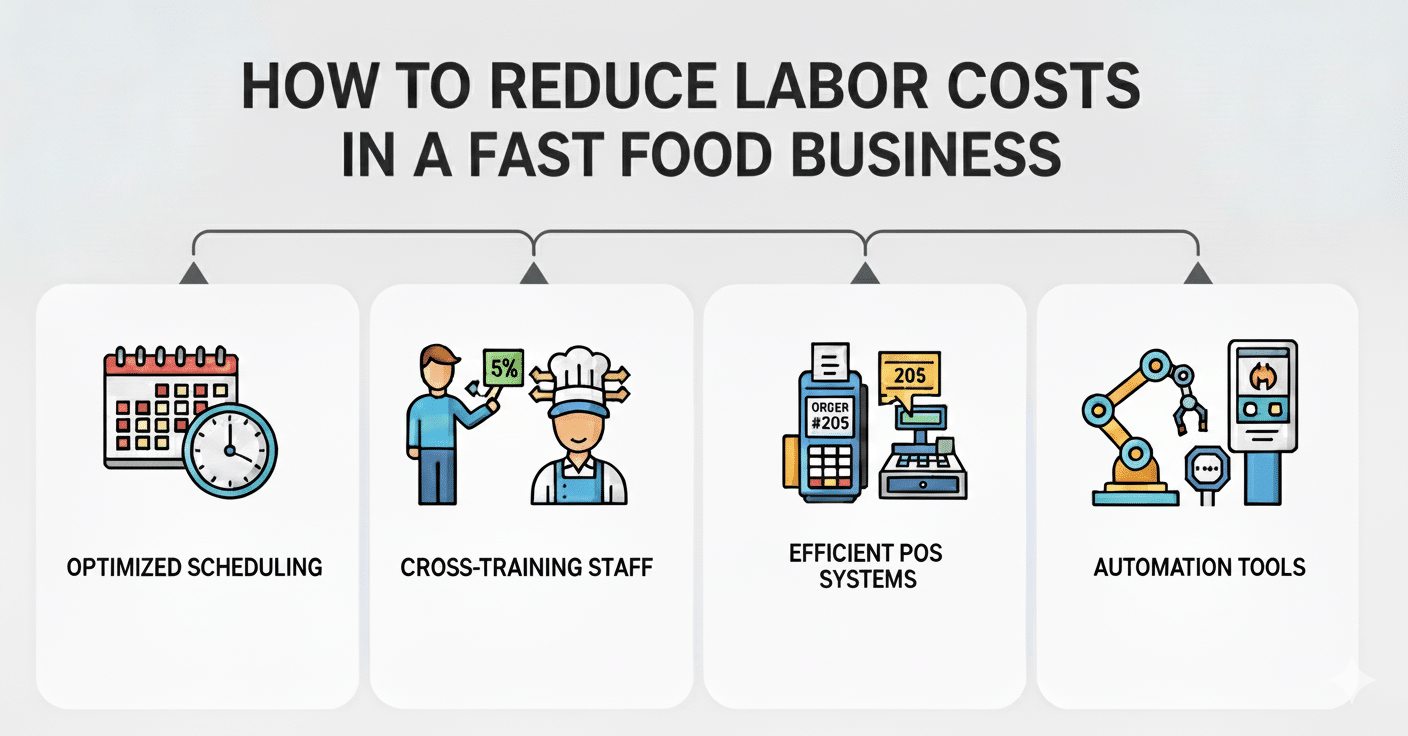

Running a fast food business comes with tight profit margins, and one of the largest expenses operators face is labor. Learning how to reduce labor costs in a fast food business without compromising service quality is essential for long-term success. By implementing smarter workforce strategies, leveraging technology, and optimizing staff efficiency, restaurant owners can save money while keeping customers happy. This article explores proven methods to control labor costs and improve overall restaurant performance.

Table of Contents

- Optimizing Staff Scheduling

- Cross-Training Employees for Flexibility

- Leveraging Automation and Technology

- Boosting Employee Productivity and Performance

- Using Data and Forecasting for Smarter Decisions

Optimizing Staff Scheduling

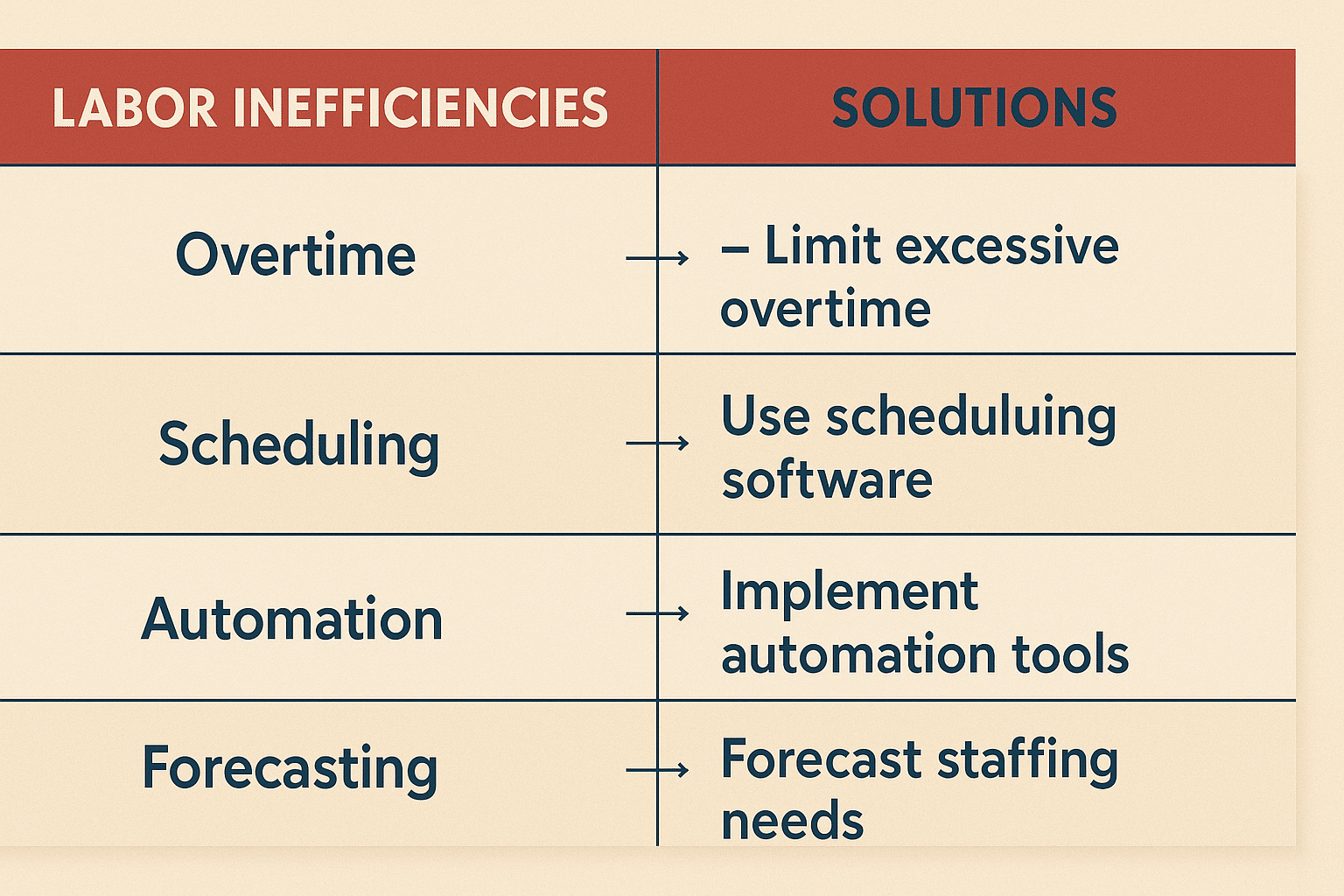

One of the most effective ways to reduce labor costs is by improving staff scheduling. Poor scheduling often results in overstaffing during slow periods or understaffing during rush hours, both of which lead to inefficiencies. By carefully planning shifts, businesses can align labor needs with customer demand and reduce wasted payroll expenses.

Using Scheduling Software

Scheduling software gives managers greater control and visibility over labor allocation. Instead of manually creating schedules, which is time-consuming and error-prone, digital tools use real-time reporting to suggest optimal staffing. This minimizes unnecessary overtime while ensuring proper coverage during peak hours. When used consistently, such software helps maintain labor efficiency in QSR environments.

For instance, scheduling platforms integrate with POS systems to analyze order history and demand forecasting. This ensures the right number of employees are working at the right time. The result is a more cost-efficient operation where employees feel supported without being overworked. Better scheduling also reduces employee turnover, another hidden labor cost many fast food businesses overlook.

In addition, these tools allow quick adjustments when unexpected situations occur, such as staff absences or sudden increases in customer traffic. Managers can swap shifts, approve time-off requests, and reassign staff instantly, avoiding costly labor inefficiencies. Therefore, adopting scheduling software is a smart step for sustainable cost control.

Another benefit of scheduling software is transparency. Employees can view their schedules in advance, swap shifts with approval, and feel more in control of their time. This builds trust and satisfaction, which reduces turnover and indirectly lowers labor costs. Happier employees often perform better, creating a win-win situation for both staff and management.

Shift Optimization Strategies

Shift optimization means aligning employee availability with business demand. For example, if Fridays and Saturdays are consistently busy, staff schedules should reflect that with more employees assigned to these shifts. On slower weekdays, schedules can be tightened to reduce labor costs without hurting service speed. This balancing act improves both cost efficiency and customer satisfaction.

Managers should also pay attention to overtime reduction when optimizing shifts. Excessive overtime quickly drives up payroll management costs, making it harder to maintain profitability. By distributing hours more evenly across staff, businesses can avoid burnout while lowering payroll expenses. This not only saves money but also builds a healthier work environment.

Furthermore, offering flexible schedules improves employee satisfaction and retention. Happy employees are more likely to stay longer, reducing the high cost of recruiting and training new staff. Shift optimization, therefore, goes beyond cutting costs—it builds a strong, motivated workforce that benefits the entire business.

Another tactic is staggering shifts. Instead of having all employees arrive and leave at the same time, staggered schedules ensure continuous coverage during transitions. This avoids downtime where too many employees are idle or not enough are available. Staggering shifts provides more precise coverage, ensuring labor dollars are spent wisely.

Integrating Demand Forecasting

Demand forecasting relies on analyzing past sales trends to predict future labor needs. For fast food businesses, this approach is invaluable because it helps managers schedule staff according to real customer patterns. Predictive scheduling ensures that peak hours are covered while reducing wasted labor during off-peak times.

For instance, if data shows that Mondays consistently have lower sales volumes, fewer staff can be scheduled on those days without affecting operations. Meanwhile, holidays or special promotions may require increased staffing. Demand forecasting ensures staffing levels are aligned with these fluctuations. This balance helps reduce labor costs in a fast food business while maintaining service quality.

When combined with real-time reporting and POS integration, forecasting becomes even more powerful. Managers can quickly identify patterns and adjust staffing in advance. As a result, businesses gain greater control over labor costs and create a smoother workflow that benefits both customers and employees.

Demand forecasting also supports proactive business planning. By understanding seasonal trends, managers can budget labor more accurately and set realistic sales expectations. This forward-looking approach improves both cost management and profitability over time.

Cross-Training Employees for Flexibility

Cross-training employees is another proven method for reducing labor costs. When workers can perform multiple tasks, managers have more flexibility in assigning roles during busy or slow periods. This reduces the need for hiring extra staff and ensures smooth operations, even when someone calls out unexpectedly.

Building Multi-Tasking Staff

Multi-tasking staff members provide fast food businesses with agility. For example, an employee trained to work both the register and the fry station can switch roles depending on customer demand. This minimizes idle time and ensures that every hour of labor adds value to the business. Cross-training is a cornerstone of effective restaurant workforce management.

Beyond daily operations, multi-tasking staff improve labor efficiency in QSR environments. They allow managers to run leaner shifts without sacrificing service speed. This means fewer employees can handle more responsibilities, reducing payroll costs while keeping customers satisfied. By investing in staff versatility, businesses create stronger teams capable of adapting to changing needs.

In addition, employees often appreciate learning new skills. Cross-training makes work more interesting and boosts morale, which helps reduce turnover. Retaining skilled employees saves money on recruitment and training, contributing further to labor cost savings.

Versatile employees also improve resilience. When a key staff member is absent, cross-trained employees can step in without disrupting operations. This prevents the business from overstaffing or hiring temporary help, both of which raise labor costs unnecessarily.

Designing Effective Training Programs

Effective training programs start with identifying core restaurant tasks such as order taking, food preparation, and cleaning. Employees can then be gradually introduced to new responsibilities under supervision. Hands-on training, shadowing, and step-by-step instruction make the process smooth and effective. This ensures that workers build confidence in their new roles.

Managers should track employee progress through performance tracking systems. Recognizing milestones not only motivates staff but also ensures consistent quality across different tasks. When training is well-structured, employees adapt faster and contribute more efficiently to operations. This creates a long-term impact on labor efficiency and cost control.

Offering incentives for employees who complete training programs encourages participation. Whether through bonuses, recognition, or career advancement opportunities, incentives make cross-training more attractive. This results in a workforce that is both skilled and motivated to take on new challenges.

Another best practice is tailoring training to employee strengths. Some staff may excel at customer-facing tasks, while others may thrive in the kitchen. Building training around these strengths ensures efficiency and confidence, making cross-training more effective in lowering labor costs.

Improving Task Delegation

Delegating tasks effectively is critical to maximizing cross-trained employees. With staff capable of handling multiple roles, managers can assign responsibilities more strategically. For example, during lunch rush, employees can be delegated to cover the busiest stations, while during downtime they can shift to cleaning or prep work. This ensures every paid hour contributes to operational efficiency.

Task delegation also prevents bottlenecks that can slow down service and frustrate customers. When managers assign roles dynamically based on need, the business adapts quickly to demand changes. This adaptability reduces unnecessary overtime and lowers payroll costs, all while keeping service standards high.

Strong delegation also helps employees develop leadership skills. When workers feel trusted to handle different roles, they become more engaged in their jobs. Engagement reduces turnover and improves overall workforce management, leading to a more stable and cost-effective business.

Delegation also helps managers focus on strategic responsibilities instead of micromanaging. This allows them to invest more time in areas like customer service, marketing, or menu innovation, which drives long-term growth and offsets labor costs.

Leveraging Automation and Technology

Technology plays a vital role in reducing labor costs in fast food businesses. Automation tools, self-service kiosks, and POS integration streamline operations while reducing the need for manual labor. By investing in technology, operators can cut costs and improve efficiency simultaneously.

Implementing Self-Service Kiosks

Self-service kiosks are increasingly common in fast food chains. They allow customers to place orders directly, reducing the need for front-line staff during peak times. This not only lowers payroll expenses but also improves order accuracy, as customers input details themselves. With fewer errors, food waste decreases, adding another layer of cost savings.

In addition, kiosks improve customer satisfaction by speeding up service. Shorter lines mean more customers served in less time, which directly boosts revenue. For businesses facing high labor costs, kiosks provide a long-term solution that balances savings with service quality. They also free up staff to focus on food preparation and customer support, making operations more efficient.

While the initial investment may seem high, the long-term payroll management benefits justify the cost. Many businesses find that kiosks pay for themselves through increased efficiency and reduced labor expenses. This makes them a practical tool for cost-conscious fast food operators.

Kiosks also generate valuable customer data, such as ordering habits and peak usage times. This data can be used to refine demand forecasting and marketing strategies, further improving profitability while helping to reduce labor costs in a fast food business.

Maximizing POS Integration

Modern POS systems do more than just process payments—they integrate with workforce management tools to streamline labor operations. By analyzing sales data, a POS system can highlight peak times and slow periods, helping managers schedule staff more effectively. This integration supports both labor efficiency and cost control strategies.

POS integration also enables real-time reporting, giving managers immediate insights into labor expenses compared to revenue. This transparency helps operators make quick adjustments to avoid overstaffing or excessive payroll costs. With accurate data at their fingertips, managers can run leaner, more profitable businesses.

Additionally, POS systems can automate payroll calculations, reducing administrative labor. This minimizes errors and saves managers time, allowing them to focus on more strategic decisions. The combination of payroll management and workforce insights makes POS integration a key tool in reducing labor costs in fast food businesses.

Another advantage is integrating POS with inventory systems. This ensures that staffing levels match not just customer flow but also supply chain realities. By aligning labor and inventory, businesses minimize inefficiencies that could otherwise drive up costs.

Automating Kitchen Operations

Automation in the kitchen includes tools like smart fryers, timers, and order display systems. These tools reduce the amount of labor required to manage food preparation, improving both efficiency and consistency. Automated equipment minimizes errors, ensuring food is cooked properly and quickly, reducing waste and labor inefficiencies.

For example, digital kitchen display systems replace paper tickets, improving communication between front-of-house and kitchen staff. This eliminates confusion, shortens prep time, and reduces the need for extra staff. As a result, fewer employees can manage a higher volume of orders, lowering payroll costs significantly.

Automation also reduces employee fatigue by taking over repetitive tasks. When staff are less stressed, they are more productive and less likely to quit. Retaining experienced staff further reduces labor costs by cutting down on hiring and training expenses. In this way, automation enhances both cost savings and employee satisfaction.

Even small tools like automatic drink dispensers or portioning machines add up to significant savings over time. Each piece of equipment that reduces manual labor contributes to payroll efficiency, helping fast food businesses operate more profitably.

Boosting Employee Productivity and Performance

Improving productivity is another direct way to reduce labor costs. When employees work more efficiently, fewer hours are needed to complete the same amount of work. This results in lower payroll expenses while maintaining high service quality.

Enhancing Order Accuracy

Order accuracy directly affects both customer satisfaction and labor costs. Incorrect orders lead to wasted food and additional labor to remake meals. By focusing on accuracy, fast food businesses can save both time and money while keeping customers happy.

Training staff on order accuracy, supported by tools such as digital POS screens, ensures fewer mistakes. Self-service kiosks also play a role by letting customers input their orders directly. This reduces misunderstandings and improves efficiency in the kitchen. With fewer errors, employees can focus on serving more customers instead of correcting mistakes.

Improved order accuracy also boosts employee productivity fast food businesses need to stay competitive. When employees spend less time fixing problems, they can complete more tasks in less time. This creates a positive cycle where efficiency leads to lower labor costs and happier customers.

In addition, order accuracy builds stronger customer trust. Loyal customers are more likely to return, increasing revenue. Higher sales volumes spread labor costs across more transactions, making the business more profitable overall.

Implementing Performance Tracking

Performance tracking involves monitoring employee efficiency, speed, and accuracy. Using key metrics, managers can identify strengths and areas for improvement. This helps ensure that every hour of labor contributes to business goals. It also provides opportunities for recognition, which boosts morale and motivation.

For instance, tracking how quickly employees serve customers during rush periods can reveal bottlenecks. Managers can then provide targeted coaching to improve performance. As employees become more efficient, labor efficiency in QSR operations increases, leading to reduced costs. Regular tracking ensures continuous improvement and accountability.

Performance data can also guide scheduling and staffing strategies. High-performing employees can be placed in critical roles during peak times, ensuring smoother operations. This use of data helps optimize labor costs while improving service speed and consistency.

Tracking also encourages healthy competition among staff. When employees see measurable results and recognition, they are motivated to improve. This enthusiasm translates into faster service and fewer errors, which saves both time and money.

Minimizing Overtime Costs

Overtime is one of the biggest hidden expenses in fast food businesses. While it may sometimes be unavoidable, excessive overtime drives up payroll costs quickly. By monitoring schedules and distributing hours fairly, managers can significantly reduce overtime expenses.

For example, workforce management tools can alert managers when employees approach overtime limits. This allows quick schedule adjustments to prevent unnecessary costs. Training staff across multiple roles also helps cover shifts without resorting to overtime. By building flexibility into schedules, businesses reduce their reliance on costly overtime labor.

Reducing overtime also benefits employees by preventing burnout. Staff who consistently work long hours may become fatigued and less productive. By keeping hours reasonable, businesses improve both efficiency and employee well-being. This creates a healthier, more cost-effective work environment overall.

Minimizing overtime also improves customer service. Energized employees are friendlier, faster, and more attentive, which creates better dining experiences. Improved service leads to repeat business, which makes payroll expenses more sustainable in the long run.

Using Data and Forecasting for Smarter Decisions

Data-driven decisions are critical in reducing labor costs in fast food businesses. By analyzing trends and applying forecasting models, managers can plan labor more effectively. This reduces waste, improves efficiency, and supports long-term growth.

Real-Time Reporting for Managers

Real-time reporting gives managers instant visibility into sales, labor costs, and employee performance. With this information, adjustments can be made on the fly to improve efficiency. For instance, if sales slow down unexpectedly, staff can be sent home early to cut costs. This responsiveness is essential for managing fast food cost control effectively.

POS integration makes real-time reporting seamless. Managers can track performance and labor expenses directly from the system dashboard. This eliminates guesswork and supports smarter, data-backed decisions. Having accurate information at the right time ensures that staffing matches actual demand, lowering wasted payroll hours.

Real-time reporting also supports accountability. Employees know their performance is monitored, which often encourages higher productivity. This transparency strengthens both management and staff efficiency, leading to reduced costs and improved results.

Another advantage of real-time data is identifying long-term patterns. By comparing week-to-week or month-to-month reports, managers can refine schedules, training, and workflows. This continuous improvement cycle ensures labor costs remain controlled over time.

Forecasting Customer Demand

Forecasting allows managers to anticipate busy and slow periods accurately. By aligning labor with demand forecasts, businesses avoid overstaffing or understaffing. This balance ensures cost efficiency while keeping service levels consistent. Demand forecasting is especially valuable during seasonal changes, holidays, and promotions.

For example, if historical data shows a spike in sales every Friday evening, managers can plan for extra staff during that time. On the other hand, scheduling fewer employees on predictable slow mornings helps reduce labor costs. This balance leads to leaner, smarter operations that maximize profitability.

Forecasting also improves employee satisfaction. When schedules are predictable and aligned with demand, staff feel less stressed and more supported. This reduces turnover, further lowering labor costs related to recruitment and training.

In addition, demand forecasting helps businesses prepare for unexpected events. Whether it’s weather-related slowdowns or sudden surges from local events, forecasting gives managers the tools to adapt quickly, saving money and maintaining efficiency.

Integrating Workforce Management Systems

Workforce management systems combine scheduling, payroll, and performance tracking into a single platform. This integration simplifies management while providing deeper insights into labor costs. Managers can easily track hours, approve time-off requests, and monitor performance from one dashboard. This streamlining reduces administrative costs and improves decision-making.

By connecting workforce systems with POS data, managers gain a full picture of how labor expenses align with sales performance. This transparency helps identify inefficiencies and opportunities for improvement. As a result, businesses maintain tighter control over labor expenses while improving service quality.

Workforce management systems also support cost control by automating repetitive tasks. Payroll processing, compliance checks, and scheduling updates are handled automatically, saving managers valuable time. This automation allows leaders to focus on strategic initiatives that drive growth and profitability.

Moreover, workforce systems create long-term consistency. Policies and procedures are enforced across multiple locations, reducing compliance risks and labor inefficiencies. This scalability is crucial for fast food chains that want to expand without letting labor costs spiral out of control.

Company Mention: At Biyo POS, we help fast food businesses streamline operations and reduce labor costs with advanced POS integration, scheduling tools, and real-time reporting. Our AI-powered solutions empower restaurant owners to cut unnecessary payroll expenses while improving efficiency and service quality. Interested operators can sign up here to start transforming their business today.

FAQ

What is the fastest way to reduce labor costs in a fast food business?

The fastest way is to optimize staff scheduling using software that integrates with POS data. This ensures labor matches customer demand, reducing wasted hours and payroll costs immediately.

How does cross-training employees save money?

Cross-training allows employees to handle multiple roles, reducing the need for extra staff. It also improves flexibility during peak and slow times, helping managers avoid overstaffing and overtime expenses.

Are automation tools worth the investment?

Yes, automation tools like self-service kiosks, kitchen display systems, and POS integration reduce payroll costs over time. They also improve order accuracy and efficiency, which saves money and boosts customer satisfaction.