If you're juggling stock across multiple stores or warehouses, you know it's a high-stakes balancing act. At its heart, multi-location inventory management is all about tracking and controlling your products across every physical site. The goal is simple: get the right products to the right place at the right time. This approach pulls you out of siloed operations and gives you a single, unified view of your entire inventory network.

The True Cost of Disconnected Inventory

When your inventory systems aren't talking to each other, the fallout hits every corner of your business—especially your bottom line. It's a surprisingly common problem that turns daily operations into a chaotic mess.

Think about this classic scenario: a customer in Austin wants your best-selling widget, but the local store is completely out. At the same time, that exact item is sitting on a shelf in your Dallas warehouse, slowly becoming dead stock. This isn't just a logistical hiccup; it's a lost sale and a ding to your brand's reputation.

The Hidden Financial Drain

The financial toll of poor inventory control is genuinely staggering. Globally, retailers lose more than $1.8 trillion annually to something called "inventory distortion"—a costly mix of overstocking and stockouts. That number tells a story about the real-world struggles of managing products across different stores, warehouses, and online channels. Every new location you open adds another layer of complexity and another chance for miscommunication, bad data entry, and delayed updates to wreak havoc. You can explore more insights about these multi-store challenges and how to tackle them.

This financial drain goes far beyond just the money you have tied up in products that aren't moving. It also shows up as:

- Bloated Carrying Costs: You're paying for storage, insurance, and labor for items that are just sitting there.

- Lost Sales Opportunities: When you can't meet demand because of a stockout, you're essentially sending customers straight to your competition.

- Painful Markdowns: Slashing prices on overstocked goods just to free up space chips away at your profit margins.

Operational Chaos and Poor Decisions

Beyond the obvious financial hits, disconnected systems create a constant state of operational friction. When your stock counts are wrong, your purchasing decisions will be, too. You might end up ordering more of a product you're already drowning in, simply because your data is inaccurate.

Without a single source of truth, teams operate on guesswork. The warehouse has no idea what the retail floor needs, and the purchasing manager is flying blind without the real-time data to make smart choices.

This breakdown leads to inefficient fulfillment, frustrated employees, and, ultimately, a customer experience that falls flat. A unified multi-location inventory management strategy isn't just a "nice-to-have" for big chains; it's a fundamental requirement for survival and growth for any business with more than one place to sell or store its goods.

Building Your Centralized Inventory Hub

If you're still juggling scattered spreadsheets to track inventory across different locations, your first and most critical move is to establish a single source of truth. Think of this as building the digital headquarters for your entire stock operation. It’s about creating one unified, reliable view that takes all the guesswork out of the equation.

This all starts with picking the right software platform. Generally, your choice boils down to two main paths: a dedicated Inventory Management System (IMS) or a more comprehensive Enterprise Resource Planning (ERP) system.

An IMS is a specialist. It’s laser-focused on tracking stock, managing purchase orders, and handling transfers with pinpoint accuracy. On the other hand, an ERP is more of an all-in-one business suite, bundling inventory with other functions like accounting, HR, and customer relationship management (CRM).

Choosing the Right System: IMS vs. ERP

For most small to medium-sized businesses, a dedicated IMS is often a great starting point. It offers a more focused, intuitive, and budget-friendly solution. ERPs are incredibly powerful, but their complexity and cost can be overkill unless you're a large enterprise needing to synchronize intricate operations across dozens of departments.

When you start evaluating software, there are a few features that are absolutely non-negotiable for effective multi location inventory management. Make sure any system you consider has:

- Real-Time Tracking: You need to see stock levels change across all locations the second a sale is made or a transfer is completed. No delays.

- Low-Stock Alerts: Automated notifications are a lifesaver. They prevent stockouts by telling you exactly when it's time to reorder for a specific location.

- Seamless Integrations: Your software has to play nice with your other tools, especially your point-of-sale (POS) systems and e-commerce platforms.

- Robust Reporting: Good decisions are driven by good data. You need access to detailed sales reports for each location to know what’s selling where.

A huge part of centralizing your inventory is gaining complete visibility into your supply chain. It's about seeing and managing everything, everywhere, in real time. For a much deeper look into this, I’d recommend exploring this guide on mastering supply chain visibility for some really practical insights.

Get Your Product Data in Order

A fancy system is useless if you feed it messy data. Before you even think about migrating, you have to standardize all your product information. This means creating a universal language for your items that every location, every employee, and every system understands.

I've seen this go wrong so many times. A store in one city calls an item "Blue-Tee-M," while the warehouse lists it as "TSHIRT_BL_MED." To a computer, those are two completely different products. This tiny inconsistency creates phantom stock, ordering errors, and a massive headache.

To avoid this chaos, get disciplined about consistency.

- Uniform SKUs (Stock Keeping Units): Design a logical, consistent SKU format and stick to it for every single product variation. Something like

BRAND-CATEGORY-STYLE-COLOR-SIZE(e.g.,BIYO-TSHIRT-VNK-BLU-MED) creates a unique, easily understood identifier for everything you sell. - Universal Barcodes: Put a barcode on everything. This single step dramatically cuts down on manual entry errors during receiving, counting, and selling. In many retail settings, this can boost accuracy by over 40%.

This data cleanup is a tedious but essential upfront investment. Once your data is clean and your system is in place, you’ll have a rock-solid foundation that not only solves today's inventory problems but can also scale with you as you grow. It also prepares you for more advanced strategies down the road. You can learn more about how clean data fuels growth by looking into different inventory forecasting techniques that help you predict what your customers will want next.

Getting Smart About Stock Levels and Transfers

Once you've centralized your inventory data, you can finally stop playing defense. The real magic happens when you shift from just reacting to stockouts and overages to proactively managing your inventory across every single location. This is where a sharp multi-location inventory management strategy truly starts to pay dividends.

The big idea is simple: have just enough of the right product in the right place when customers want it. This means throwing out the old one-size-fits-all approach to reordering. A hot-seller in your downtown flagship might just gather dust in a suburban mall. Your system needs to be nimble enough to set unique reorder points for each location, driven by local sales history, foot traffic, and even regional trends.

The Power of Intelligent Stock Transfers

One of the best tools in your new arsenal is the intelligent stock transfer. Instead of scrambling when one store sells out while another is buried in the same product, you can see the imbalance coming and shift inventory before it becomes a problem. This isn't just about shuffling boxes; it's a strategic move to get the most out of every single item you own.

Picture a clothing brand with stores in Miami and Denver. As the first chill of fall hits, demand for heavy coats is obviously going to spike in Denver while staying nonexistent in sunny Miami.

- The Old Way: The Miami store is stuck with winter coats it can't sell, eventually marking them down for a loss. At the same time, the Denver shop blows through its initial stock and misses out on weeks of prime selling season waiting for a new delivery.

- The Smart Way: The system flags the sales trend. The company initiates a transfer, sending the excess coats from Miami straight to Denver. The result? They meet soaring demand in Colorado, avoid steep discounts in Florida, and turn a potential loss into a win.

This kind of proactive rebalancing is a game-changer. Especially today, with supply chains being so unpredictable, having this internal agility is a huge competitive edge. Modern centralized systems can dramatically cut down on errors and boost efficiency, often using AI-driven analytics to keep a constant, real-time pulse on stock levels.

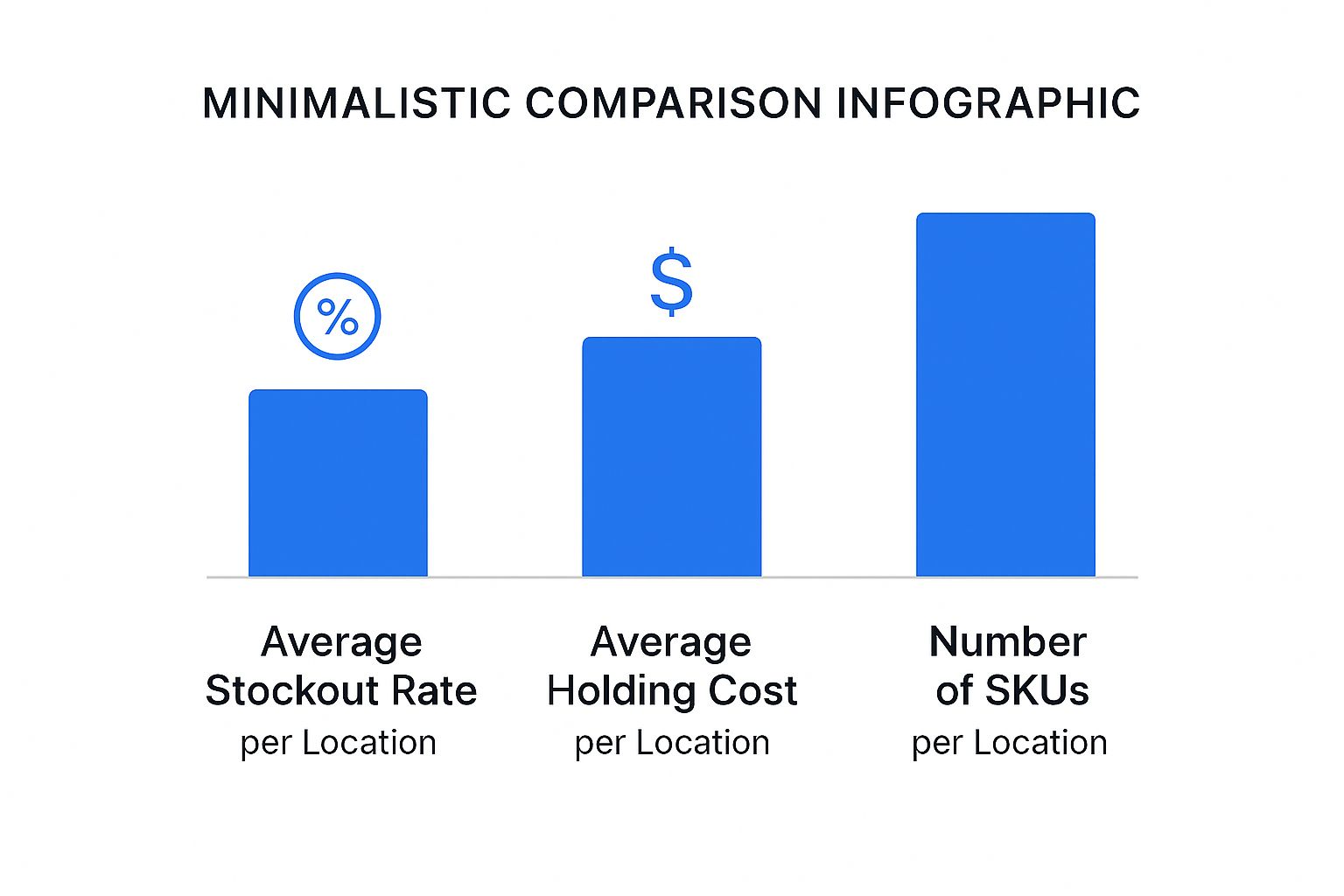

The chart below shows some of the key metrics businesses use to spot these optimization opportunities across their network.

When you can see your data laid out like this, it becomes immediately clear which locations are burdened by high holding costs and which are constantly disappointing customers with high stockout rates.

To get the most out of your inventory, it's crucial to select the right optimization model. Different businesses have different needs, so what works for a fast-fashion retailer might not be suitable for a B2B parts supplier.

Inventory Optimization Techniques Compared

| Technique | Best For | Key Benefit | Implementation Complexity |

|---|---|---|---|

| ABC Analysis | Businesses with a wide range of SKUs | Prioritizes high-value "A" items | Low |

| Just-in-Time (JIT) | Companies with predictable demand and reliable suppliers | Minimizes holding costs and waste | High |

| Economic Order Quantity (EOQ) | Stable demand and consistent ordering costs | Balances ordering and holding costs perfectly | Medium |

| Safety Stock Analysis | Businesses facing demand or lead time uncertainty | Prevents stockouts from unexpected spikes | Medium |

Choosing the right technique, or a combination of them, depends entirely on your product mix, supply chain reliability, and customer demand patterns. The goal is always the same: to reduce costs while keeping customers happy.

Think of your entire network of stores as one giant, interconnected inventory pool. A product isn't just "at the Miami store"—it's a company asset, ready to be deployed wherever it can create the most value.

This shift in mindset is critical. For a deeper dive into managing company assets across their entire journey, looking into the real-world advantages of asset lifecycle management offers some fantastic parallels. When you treat every piece of inventory with this level of strategic care, you give it the absolute best chance of being sold at full price.

Using Technology for Better Accuracy and Insight

Good inventory management is built on solid processes. But truly great multi location inventory management? That runs on technology. The right tools can take your operations from a series of manual, mistake-prone chores to a data-rich system that gives you a real competitive edge. It’s all about working smarter, not just harder.

The most immediate change you'll see comes from tools like barcode or Radio Frequency Identification (RFID) scanners. Think about the old way of receiving a shipment or doing a stock count—it's slow, tedious, and a perfect recipe for human error. A single mistyped number can throw off your entire count for a product.

In contrast, scanning a barcode is instant and nearly perfect. Research has shown that automated data capture can slash inventory errors by over 40%. This one upgrade drastically cuts the time your team spends on manual data entry, freeing them up for things that actually grow the business, like helping customers or improving store displays.

Predicting the Future with AI and Machine Learning

While scanners get your real-time data right, Artificial Intelligence (AI) and Machine Learning (ML) help you understand what that data means for the future. These tools are completely changing demand forecasting. They go way beyond looking at last year's sales to predict what’s coming next with stunning accuracy.

An AI-powered system can spot patterns a person would almost certainly miss by analyzing countless variables at once.

- Local Events: Is a huge festival happening near one of your stores? The system can predict a run on certain items.

- Weather Patterns: An incoming heatwave might signal a rush on summer clothing in one city, but not another.

- Competitor Promotions: Smart systems can even track competitor sales and promotions to anticipate shifts in customer behavior.

Having this kind of foresight lets you be proactive with your inventory. For a restaurant, this predictive ability is a lifesaver, minimizing food waste while making sure you never run out of a popular dish. You can dig deeper into how a modern system helps you master your restaurant inventory management system and make better purchasing calls.

Technology’s role isn't to replace your team's expertise; it's to supercharge it. By automating repetitive tasks and providing deeper analytical insights, you empower your people to make faster, more informed decisions that directly impact profitability.

To tighten control even further, you can also use technology to implement advanced shipping restrictions. This is a practical way to ensure products are only sent where they're supposed to go, which helps with compliance and keeps your logistics network running smoothly. The ultimate goal is to build a single, tech-driven system where accuracy and insight flow seamlessly across all of your locations.

How Distributed Warehousing Slashes Your Shipping Bill

Bringing your inventory closer to your customers is a game-changer. It fundamentally flips your shipping and fulfillment from a necessary evil into a genuine competitive edge. Think about it: the core idea is all about proximity.

Instead of every single order making a long journey from one central hub, you fulfill it from the closest regional facility. That cross-country shipment that used to take five days and cost a fortune? Now, it might just be a local drop-off. This isn't a small tweak; it’s a complete overhaul of your logistics that directly leads to faster delivery and much lower shipping costs.

The Impact on Your Wallet and Your Customers

This distributed model isn't just theory—it delivers real, measurable results. Spreading your stock out intelligently means you can ship from the nearest possible point, and that alone can chop your freight expenses by up to 20% compared to sticking with a single warehouse. The savings come directly from shorter delivery routes. It's that simple. You can dig into more of the numbers behind these multi-location warehouse management savings to see how it all breaks down.

But the real magic happens when you see the impact on your customers. We all know people expect fast delivery these days, and this strategy is how you deliver on that promise.

- Happier Customers: Turning a standard two-day delivery into an overnight—or even same-day—surprise is a fantastic way to build loyalty. People remember that kind of service.

- More Completed Sales: When shoppers see fast and cheap shipping options at checkout, they're far less likely to abandon their carts.

- A Stronger Brand: You quickly get a reputation for being fast and reliable, which builds incredible trust and makes you stand out.

Keeping Your Network Running Smoothly

Of course, none of this works if it's a chaotic mess behind the scenes. The whole operation hinges on a central management system that acts as the brain for your entire network. This is where you’ll find some of the best retail POS software with built-in inventory management—the tools that tie all your locations together.

With a unified system, each warehouse isn't an island. It's a synchronized part of a larger, smarter network. The system can automate purchase orders based on local demand and ensure your pick-and-pack process is identical everywhere, which keeps things consistent and accurate.

This kind of control is what cuts down on manual work, reduces labor costs, and practically eliminates fulfillment errors. At the end of the day, distributed warehousing is about so much more than just saving a few bucks on shipping. It’s about building a fulfillment operation that’s tougher, more efficient, and completely focused on your customer.

Answering Your Top Questions on Multi-Location Inventory

Moving to a more advanced inventory strategy is a big step, so it’s natural to have questions. Let's walk through some of the most common things business owners ask when they’re getting started with multi-location inventory management.

What Is the Biggest Challenge in Multi-Location Inventory Management?

Hands down, the single biggest hurdle is getting a clear, real-time picture of your stock across every single location. Without a unified system, each store or warehouse basically operates on its own little island. This isolation forces you into guesswork, which is always expensive.

This lack of connection is where most problems start. You’ll have stockouts in one store while another location is drowning in the exact same product, leading to lost sales and bloated carrying costs. A centralized platform is the only real fix, giving you one source of truth for all your inventory, everywhere.

How Do I Choose the Right Inventory Management Software?

The right software for you really depends on your business—your size, where you sell, and where you plan to be in a few years. It's critical to pick a system that solves today's headaches but won't hold you back when you grow.

When you're comparing options, here are the non-negotiables:

- Real-Time Data Syncing: When an item sells in one place, that change needs to show up everywhere, instantly.

- Automated Reordering: You should be able to set custom reorder points for each location to automatically prevent stockouts.

- Robust Reporting: You need analytics that break down sales trends by location so you can see what's really happening on the ground.

- Seamless Integration: The software has to play nicely with the tools you already use, like your POS and e-commerce platform.

Think of your software as the central nervous system for your entire operation. Choosing a scalable solution from day one saves you from the massive pain of having to switch systems later on when your business takes off.

Is This Strategy Useful for Small Businesses?

Absolutely. This isn't just a game for the big retail chains. Any business with more than one place to hold stock—even if it's just two small shops or a retail store and a backroom warehouse—will see huge benefits.

It helps you avoid that classic frustrating moment: telling a customer an item is out of stock when you actually have it just a few miles away. More importantly, it sets you up for growth. You build efficient habits and systems early, before things get so chaotic that they become a nightmare to fix.

What Is the Difference Between Multi-Warehouse and Multi-Location Inventory?

It's helpful to think of multi-location inventory management as the big umbrella term. It covers managing stock across any place you hold or sell it—this could be retail stores, warehouses, pop-up shops, or even a fleet of service vans.

Multi-warehouse management is just one piece of that puzzle. It's specifically about optimizing inventory across multiple distribution centers, which is a common setup for e-commerce and wholesale businesses. Ultimately, both fall under the same core need: a central system to track your products across a distributed network.

Ready to gain complete control over your inventory, no matter how many locations you have? Biyo POS offers a powerful, all-in-one system that unifies your stock, sales, and customer data in real-time. Stop the guesswork and start making smarter, data-driven decisions today. Explore Biyo POS to see how it works.