When we talk about food costing, we're getting into the nitty-gritty of what it costs to create every single dish on your menu. This isn't just about crunching numbers for your accountant; it's a fundamental strategy for survival and success in the restaurant business. It helps you manage what you buy, keep a lid on expenses, and make sure every plate you send out is actually making you money.

Why Food Costing Is Your Restaurant's Secret Ingredient

A lot of restaurateurs I've met treat food costing like a chore. It's that tedious spreadsheet work you put off until the end of the month. But seeing it that way is a huge mistake. Think of precise food costing as the strategic heart of your operation—it's what turns a passion project into a profitable business. It’s the difference between guessing where your money is going and knowing.

Here’s a classic scenario: your signature burger is flying out of the kitchen. You're selling hundreds a week and think it's your star player. But without accurate costing, you might not realize that the rising price of that prime beef, the fancy artisan buns, and your special sauce have quietly turned it into a money pit. You're celebrating a popular dish that's secretly draining your bank account with every order. I've seen it happen time and time again.

The Foundation of Financial Control

When you get food costing right, you get a crystal-clear, data-backed picture of your kitchen's financial health. It's the bedrock for every other smart decision you make. Once you know the exact cost of a dish, you gain serious control over key parts of your business:

- Informed Menu Pricing: Forget that old-school "triple the cost" rule. Knowing your precise plate costs lets you set prices that ensure a healthy profit margin on every item.

- Smarter Inventory Management: When you track exactly how much of each ingredient you're using, you stop over-ordering and cut down on spoilage. This is a direct hit against waste, one of the biggest cash drains in any kitchen.

- Stronger Supplier Negotiations: Armed with data on your ingredient usage and price trends, you can walk into negotiations with your suppliers with real leverage to get better deals.

- Profitability Analysis: You can quickly spot which dishes are your cash cows and which ones are just taking up space on the menu. This is how you start engineering your menu for maximum profit.

Without a firm grasp on food costs, a restaurant is essentially flying blind. You're making critical business decisions based on assumptions rather than facts, which is a recipe for failure in a competitive market.

Thriving in a Challenging Market

Let's be honest, the restaurant industry is tough. Margins are razor-thin. We're looking at a global foodservice market that hit $3.09 trillion in 2024 and is expected to climb past $4.1 trillion by 2033. But even with all that money flowing, the average net profit margin is still stuck at a slim 3% to 5%.

That leaves absolutely no room for error. Precise cost control isn't just a "nice-to-have" anymore; it's essential. When you start treating food costing as your primary tool for navigating your finances, you're building a restaurant that can do more than just survive—it can truly thrive. You can dig deeper into restaurant industry statistics to get a better sense of the competitive landscape we're all working in.

Calculating Your True Food Cost Percentage

Alright, let's get to the number that really matters—the one that shows you the financial pulse of your kitchen. Calculating your true food cost percentage isn't just some accounting chore. It's the clearest, most direct way to see how well you're turning raw ingredients into cash in the bank.

This single percentage tells you exactly how much of your revenue is being spent on the food itself. Think of it as your kitchen's core health metric.

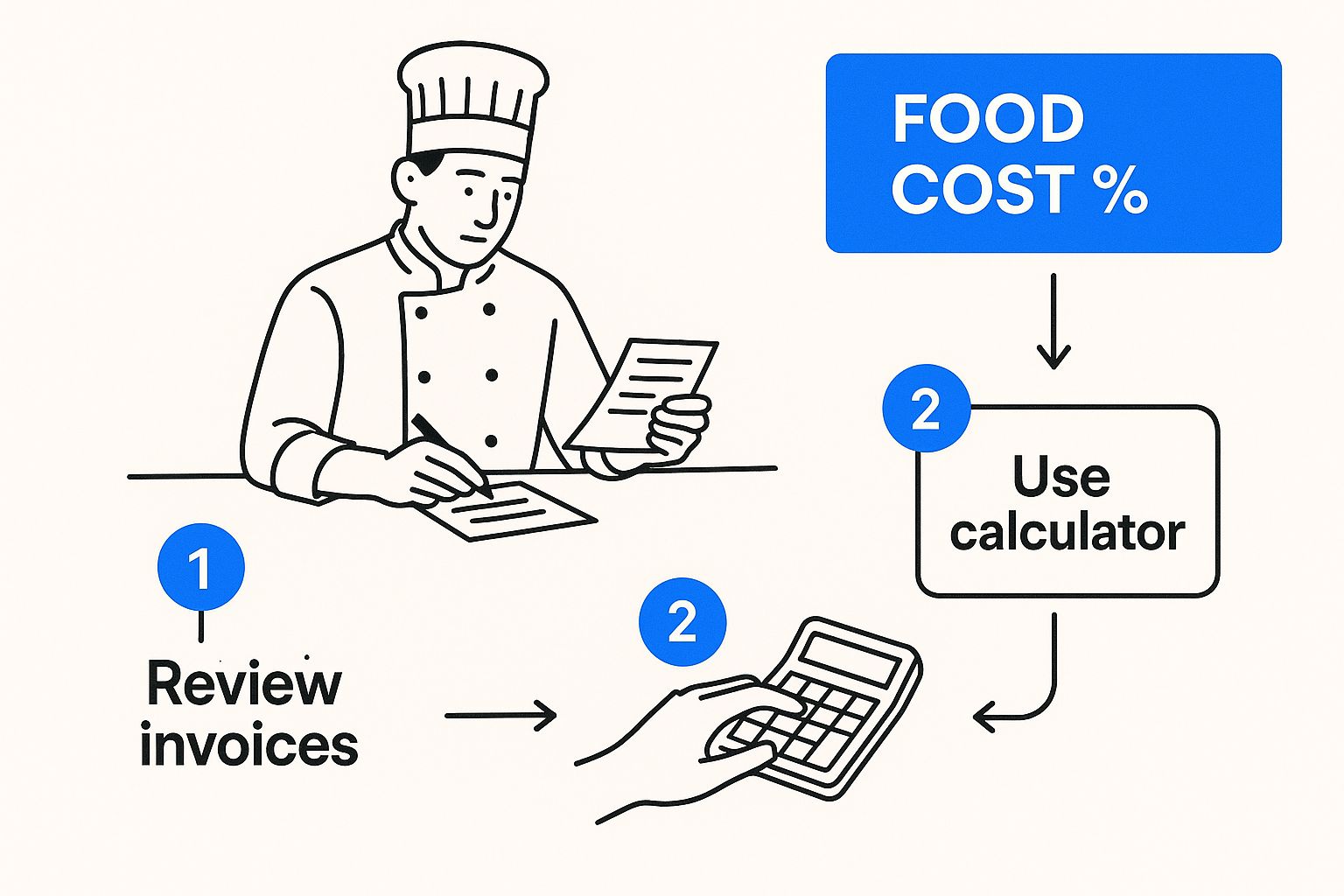

The formula itself is pretty simple, but its power comes from getting the inputs right. You'll need to track your inventory and purchases over a specific period, usually a week or a month.

Food Cost % = (Beginning Inventory + Purchases – Ending Inventory) / Food Sales

What this gives you is your actual food cost. It's the real-world number that accounts for everything that happens in your operation—the good (sales), the bad (waste), and the ugly (theft).

Breaking Down The Food Cost Formula

To get a number you can actually rely on, you have to be precise with every part of that equation. Let’s walk through it with a real-world example. Imagine we're running the numbers for a small cafe for the first week of the month.

- Beginning Inventory: This is the dollar value of every single food and beverage item you have on hand right before you start the period. For our cafe, let's say we do a full count Monday morning before the doors open, and the total value comes out to $10,000.

- Purchases: This is the total cost of all the food and drink you bought during the week. Our cafe owner pulls all the supplier invoices from Monday through Sunday and finds they spent $4,000.

- Ending Inventory: Time to count again. At the very end of the period (say, Sunday night after you've locked up), you do another full inventory count. Let's say our cafe’s stock is now valued at $9,500.

- Food Sales: This is the easy part. Just pull the total food sales figure for that same week directly from your POS system. Our cafe's report shows they brought in $15,000.

Now, we just plug those numbers into our formula:

($10,000 + $4,000 – $9,500) / $15,000 = $4,500 / $15,000 = 0.30

Multiply that by 100 to get the percentage, and there you have it. Our cafe’s food cost for the week is 30%.

The image below gives you a great visual of how this all comes together, showing a chef pulling together invoices and inventory sheets to land on that critical number.

As you can see, getting your food cost right is a hands-on process. It’s where your diligence in the stockroom meets your financial tracking in the office.

Sample Weekly Food Cost Calculation

Here is a practical example showing how a small restaurant would calculate its actual food cost percentage over one week.

| Metric | Value ($) |

|---|---|

| Beginning Inventory | $10,000 |

| Purchases | $4,000 |

| Ending Inventory | $9,500 |

| Food Sales | $15,000 |

| Cost of Goods Sold | $4,500 |

| Food Cost Percentage | 30.0% |

This table clearly lays out how the inputs flow through the formula to produce the final food cost percentage, a key performance indicator for any food service business.

Don't Forget The Hidden Costs

Just running the numbers isn't quite enough. A classic mistake is forgetting to account for all the inventory that leaves your shelves without generating a sale. If you ignore these items, your food cost will look artificially high, and you might think your kitchen is struggling more than it is.

To get a truly accurate picture, you need to track and subtract the value of things like:

- Employee Meals: The cost of the food you provide to your staff.

- Spoilage and Waste: Any ingredients tossed due to spoilage, cooking mistakes, or customer returns.

- Comped Items: Food you give away for free, whether it's to fix a mistake or as a marketing gesture.

Let's go back to our cafe. If the owner figures out that $200 worth of food was used for staff meals and waste that week, the true cost of goods sold is actually $4,300 ($4,500 – $200). This drops the adjusted food cost percentage to 28.6% ($4,300 / $15,000), which is a much more accurate reflection of their performance.

Mastering this detailed approach to food costing is the foundation for building a smarter, more profitable menu. Once you have a reliable number you can trust, you can start creating a restaurant menu pricing strategy that actually protects your margins on every single plate that leaves the kitchen.

Getting to the Real Cost of Every Plate on Your Menu

Knowing your overall food cost is like looking at your restaurant from 30,000 feet. It’s useful, but the real magic happens on the ground. To truly control your profitability, you have to get granular and figure out the exact cost of every single dish that comes out of your kitchen. This is what we call the plate cost, and it’s the bedrock of a smart, profitable menu.

Moving from a general food cost percentage to individual plate costs is a game-changer. It’s the only way to know if that best-selling burger is actually making you money or quietly draining your bank account. It takes some serious attention to detail, but believe me, the payoff is huge.

Build Your Recipe Bible: The Standardized Cost Sheet

First things first: every single item on your menu needs a standardized recipe. This isn't just about making sure the dish tastes the same every time—it's a critical financial tool. This recipe cost sheet has to list every last component, right down to the garnish.

Let’s take a simple pasta carbonara. You’d obviously list the big-ticket items like pancetta, Pecorino Romano, and pasta. But what about everything else?

- The splash of white wine you use to deglaze the pan.

- The pinch of black pepper on top.

- The olive oil for the sauté.

- The slice of bread served on the side.

Forgetting these "little" things can easily skew your costs by 5-10%. Over a year, that adds up to thousands of dollars walking out the door.

Your goal is to create a living document for each dish. This cost sheet becomes your single source of truth, ensuring every plate is made the same way, for the same cost, every single time.

The Not-So-Fun Part: Kitchen Math

One of the biggest headaches in food costing is converting supplier units into recipe units. You buy beef by the case and flour by the 50-pound bag, but your recipes call for ounces and cups. This is where you have to roll up your sleeves and do a little math.

For example, say you buy a 10-pound case of ground beef for $50. That’s an easy $5 per pound. But your burger recipe calls for a 6-ounce patty.

To find the actual cost of that one patty, you have to break it down:

- Cost per pound: $5.00

- Ounces in a pound: 16

- Cost per ounce: $5.00 / 16 oz = $0.3125

- Cost per 6-ounce patty: $0.3125 x 6 oz = $1.88

You have to do this for every single ingredient in every single recipe. It's tedious, I know. This is where a good POS system with inventory management features, like those from Toast or Lightspeed, can be a lifesaver. They handle these conversions automatically, which cuts down on hours of work and costly human error.

Don't Forget About Waste and Shrinkage

Here’s a rookie mistake I see all the time: forgetting about yield loss. You never get to use 100% of what you buy. You trim fat from a steak, peel potatoes, and meat shrinks when you cook it. All of this loss has to be baked into your plate cost.

Let’s say you buy a whole 4-pound chicken for $12. After it’s roasted and deboned, you’re left with maybe 2.5 pounds of usable meat.

- As-Purchased (AP) Cost: $12 / 4 lbs = $3.00 per pound

- Edible Portion (EP) Weight: 2.5 lbs

- Your True Cost: $12 / 2.5 lbs = $4.80 per pound

If you used the $3.00/lb price for your chicken salad recipe, you’d be under-costing it by a staggering 60%! Calculating the yield for your core ingredients is absolutely non-negotiable if you want accurate numbers.

Nailing this down is more critical than ever. The National Restaurant Association’s data shows the Producer Price Index for food was 37% higher in July 2025 than five years prior. We're seeing huge jumps in key ingredients like finfish (31.9%), eggs (25.3%), and fresh vegetables (20.9%). You can read more about the impact of food costs on restaurants on their site.

With wholesale prices climbing like this, having a precise understanding of your plate costs is the only way to adjust your menu prices intelligently without scaring off your guests. Once you’ve built this solid foundation, you’re ready for the next step: pricing your menu for maximum profit.

Pricing Your Menu for Maximum Profitability

Once you’ve nailed down your exact plate costs, you can finally price your menu with real confidence. Forget outdated rules of thumb. The old "just multiply the cost by three" trick is a recipe for disaster in today's market. Smart menu pricing is a delicate balance—part science, part art—that keeps customers happy while making sure your restaurant actually turns a profit.

This is where all that detailed food costing work really pays off. It lets you move beyond guesswork and use pricing strategies that protect your margins on every single dish. Let's dig into two of the most effective methods that successful restaurants use to build menus that are both appealing and incredibly profitable.

The Ideal Food Cost Percentage Method

This is probably the most common and straightforward way to price a menu. The idea is simple: you set a price for each dish to hit a specific, target food cost percentage.

Let's say your target food cost is 30%, and your signature burger costs you $4.50 in ingredients. The math is easy.

Menu Price = Plate Cost / Target Food Cost Percentage

For our burger, that looks like: $4.50 / 0.30 = $15.00

Using this method ensures every item sold contributes predictably to your bottom line. It’s a solid, reliable way to build consistent margins across the entire menu.

Prioritizing Dollars with Contribution Margin Pricing

The percentage method is great for consistency, but it has a major blind spot: it doesn't tell you how much actual cash each dish puts in your till. That’s where contribution margin pricing comes in. It’s a technique savvy operators lean on to maximize raw profit dollars.

Simply put, the contribution margin is what’s left after you subtract the plate cost from the menu price. It’s the cash that "contributes" to paying for labor, rent, and all your other overhead—and what's left over is your profit.

Instead of focusing on a percentage, this strategy prioritizes the actual dollar profit per dish. You might find that a lower-cost item has a higher food cost percentage but a much larger contribution margin, making it far more valuable to your business.

Let’s compare two dishes:

| Menu Item | Plate Cost | Menu Price | Food Cost % | Contribution Margin |

|---|---|---|---|---|

| Gourmet Burger | $6.00 | $18.00 | 33% | $12.00 |

| Chicken Pasta | $3.50 | $15.00 | 23% | $11.50 |

At first glance, the pasta looks like the winner with its lean 23% food cost. But look closer. The burger, despite its higher 33% food cost, actually drops an extra $0.50 in pure cash into your pocket with every single sale. This is exactly why understanding contribution margin is so critical.

Finding the Right Balance for Your Menu

So, which one is better? The truth is, you shouldn't choose. The smartest operators blend both methods.

Use the ideal food cost percentage as your starting point to set a baseline price for every item. Then, dig into the contribution margin for each dish to identify your real profit-drivers. This powerful combo is the key to creating a balanced menu that keeps guests coming back while padding your bottom line.

Getting this level of detail is more important than ever. In the United States, full-service restaurant menu prices shot up by 4.1% year-over-year as of March 2025, a direct result of rising ingredient and labor costs. This constant pressure means you have to be precise with your costing just to stay afloat. Mastering these pricing strategies is a core component of our guide on restaurant management strategies for maximum efficiency.

Everyday Strategies to Reduce Your Food Costs

Knowing your numbers is one thing, but actually controlling them day-in and day-out is how you win the restaurant game. Mastering your food cost isn't a one-and-done calculation; it's a daily habit of making smart decisions that protect your profit margins. This is where all that detailed analysis pays off in real-world savings that you'll see on your bottom line.

The good news? You don’t have to completely overhaul your kitchen. Small, consistent tweaks to your daily routines can lead to some serious savings, all without sacrificing the quality your guests expect. Let's dig into a few practical strategies you and your team can start using today.

Master Smart Purchasing and Receiving

The first line of defense against high costs is right at the back door—your suppliers. Strong purchasing habits are the bedrock of cost management. If you're just accepting the list price on every invoice without question, you're leaving money on the table.

Start by building real relationships with your vendors. When you have a solid rapport, it's much easier to negotiate better pricing, ask about volume discounts, or get a heads-up on special deals. And don't get complacent; always compare prices between a few different suppliers for your key ingredients. A little bit of shopping around keeps everyone honest.

Beyond the negotiation, you need a bulletproof receiving process. Every single delivery must be checked with a fine-toothed comb.

- Verify Quantities: Does the box count match the invoice? Is the weight correct?

- Check Quality: Is the produce actually fresh? Are the proteins at a safe temperature?

- Confirm Pricing: Does the price on this invoice match the price you were quoted?

Don't be afraid to reject anything that doesn't meet your standards. Taking a subpar product just to avoid a difficult conversation will only cost you more later in waste and unhappy customers.

Implement Ironclad Inventory Controls

Your storeroom can either be a goldmine of savings or a black hole where profits disappear. The difference lies in how you manage your inventory. The First-In, First-Out (FIFO) method is the golden rule here. It’s a simple concept: older stock always gets used before newer stock. This alone can drastically cut down on spoilage.

To make FIFO a reality, your team has to be trained to organize the walk-in and dry storage properly. New items always go behind existing ones. Label everything with the delivery date. This little bit of organization is a game-changer.

A messy storeroom is a direct line to food waste. It’s shocking, but studies show that a staggering 85% of unused food in American restaurants gets thrown out. Simple systems like FIFO are one of the most powerful tools you have to fight this profit drain.

You should also be doing regular inventory counts. While you might only do a full, wall-to-wall count once a month, try implementing weekly "flash counts" for your most expensive and perishable items. Things like prime steaks or fresh seafood. This helps you spot usage problems, over-portioning, or even potential theft much faster.

Engineer Your Menu for Higher Profits

Your menu is so much more than a list of food. It's your number one sales tool. Menu engineering is all about digging into your sales data to figure out which dishes are popular, which are profitable, and how you can subtly guide customers toward the items that make you the most money.

Get started by breaking down your menu items into four simple categories based on their profitability and popularity.

- Stars: High profit, high popularity. These are your champions. Feature them, talk about them, and make them shine.

- Puzzles: High profit, low popularity. These items have potential but aren't selling. Try moving them on the menu, writing a more delicious description, or having servers recommend them.

- Plowhorses: Low profit, high popularity. Everyone loves these, but they don't make you much cash. Could you raise the price just a bit? Or maybe re-work the recipe with a slightly less expensive ingredient?

- Dogs: Low profit, low popularity. These are weighing you down. It's probably time to take them off the menu.

Once you understand this mix, you can make strategic moves that directly boost your bottom line. Sometimes, a simple recipe tweak or a more enticing name can turn a "Puzzle" into a "Star." These menu strategies, paired with smart purchasing and inventory control, create a powerful system that’s a key part of learning how to increase restaurant sales and grow your business sustainably.

Your Top Food Costing Questions Answered

Even after you’ve nailed down the formulas, the day-to-day reality of restaurant food costing can throw some curveballs. Let’s walk through some of the most common questions I hear from owners and managers trying to get their numbers right.

Think of these as the real-world hurdles that separate a profitable restaurant from one that's just spinning its wheels. Getting these details right is what builds a financially resilient business.

How Often Should I Calculate My Food Cost?

This is a big one. The short answer? As often as you can manage, but with a clear minimum.

Ideally, you should be calculating your actual food cost percentage at least once a week. Doing it weekly gives you fresh, actionable data. It lets you catch a problem—like a sudden price jump from a supplier or a waste issue on the line—before it has a chance to sink a whole month's profits.

If a full weekly inventory is just too much for your team right now, a monthly calculation is the bare minimum. Any less frequently, and you're essentially flying blind. By the time you get the numbers, they're history, not a tool you can use to make immediate changes.

What’s The Difference Between Actual And Theoretical Food Cost?

Getting your head around this is a game-changer for spotting hidden profit leaks in your kitchen. It's one of the most critical concepts in advanced food costing.

-

Theoretical Food Cost: This is your "on paper" or "perfect world" cost. It's what your food cost should be if every single ingredient was used perfectly according to the recipe, with zero waste, no mistakes, and perfect portioning. You calculate it using your sales mix and standardized recipes.

-

Actual Food Cost: This is the real-world number you get from the inventory formula we covered. It accounts for everything that actually happened—all the waste, spills, over-portioning, employee meals, comped dishes, and even potential theft.

The difference between these two numbers is called the variance. It tells a story. A tiny variance of 1-2% is expected, but if that gap gets bigger, it’s a red flag. It’s pointing directly to money lost from waste, poor portion control, or other operational slip-ups.

Should I Include Paper Goods In My Food Cost?

Absolutely not. While things like to-go boxes, napkins, and plastic cutlery are definitely a cost of goods sold, mixing them in with your food ingredients will completely skew your numbers.

When you lump them together, you can no longer see how efficiently your kitchen is actually using its food inventory. It muddies the water.

The best practice is to track these items on their own line in your P&L statement, often called "Paper Goods" or "Packaging Costs." This gives you a much cleaner view of your finances, allowing you to manage food and packaging expenses separately.

By separating them, you can see precisely where your money is going. If packaging costs are creeping up, you can shop for new suppliers without mistakenly blaming your kitchen team for a food waste problem that doesn't exist. Clean data leads to smart decisions.

Ready to take full control of your restaurant's finances? Biyo POS integrates inventory management and sales reporting to make food costing simple and automatic. See exactly where your money is going, optimize your menu for profit, and stop guessing. Start your free 14-day trial today and see how easy it can be.