Inventory decisions shape cash flow, customer satisfaction, and daily operations for growing companies. This is why Inventory Forecasting for Small Businesses has become a critical skill rather than a luxury. When forecasting is done well, owners can anticipate demand, reduce waste, and keep shelves stocked without tying up unnecessary capital.

Many small businesses still rely on intuition or last-minute reordering. While experience helps, it often fails during seasonal shifts or sudden demand changes. A structured approach to inventory forecasting helps businesses move from reactive decisions to proactive planning.

This article explains how Inventory Forecasting for Small Businesses works in practice, which methods deliver reliable results, and how modern tools simplify the process. Along the way, we will explore demand forecasting inventory strategies, inventory analytics, and supply planning techniques that support sustainable growth.

Table of Contents

- Understanding Inventory Forecasting Basics

- Inventory Forecasting Methods That Work

- Using Data and Inventory Analytics

- Inventory Planning Tools for Small Teams

- Avoiding Overstocking and Stockouts

- How Biyo Helps with Inventory Planning

- Frequently Asked Questions

Understanding Inventory Forecasting Basics

Inventory forecasting refers to the process of predicting future stock needs based on data, trends, and business goals. For small businesses, forecasting creates stability by reducing guesswork and improving purchasing decisions.

Why Forecasting Matters for Small Businesses

Small businesses operate with limited margins and tighter cash flow. Because of this, excess inventory can quickly strain finances and storage capacity. Accurate forecasting reduces unnecessary spending and protects working capital.

At the same time, understocking creates missed sales and frustrated customers. When products run out unexpectedly, loyalty suffers. Inventory Forecasting for Small Businesses balances availability with efficiency.

By planning ahead, owners gain confidence in ordering decisions. As a result, they can focus more on growth and less on emergency restocking.

Forecasting works best when it connects sales history with future expectations. This connection allows small teams to compete with larger organizations.

The Role of Demand Forecasting in Inventory

Demand forecasting inventory techniques estimate how much customers will buy in a future period. These estimates rely on historical sales data and market trends.

For instance, a retailer may notice higher demand during holidays. Meanwhile, a café might see spikes during weekends. Recognizing these patterns improves stock demand prediction.

When demand forecasting aligns with purchasing cycles, businesses avoid last-minute orders. Therefore, lead times become easier to manage.

Consistent forecasting builds predictability. Over time, this predictability improves supplier relationships and pricing.

Key Metrics Used in Forecasting

Several metrics guide effective forecasting. Inventory turnover measures how often stock sells and replenishes. Higher turnover often signals healthy demand.

Sales velocity shows how quickly products move. Meanwhile, average order value helps estimate future volume. These metrics work together.

Tracking these indicators supports Inventory Forecasting for Small Businesses by grounding decisions in measurable performance rather than assumptions.

Over time, these metrics reveal patterns that inform smarter planning.

Inventory Forecasting Methods That Work

Inventory Forecasting Methods That Work

Different businesses require different forecasting approaches. The best method depends on sales volume, seasonality, and data availability.

Historical Sales-Based Forecasting

This method uses past sales data to predict future demand. It works well for businesses with stable sales patterns.

For example, if a product sells 100 units monthly, future orders can follow that trend. Adjustments account for known events or promotions.

Inventory Forecasting for Small Businesses often begins here because historical data is easy to access. However, this approach assumes conditions remain consistent.

When markets shift, historical data alone may fall short. Therefore, regular review remains essential.

Trend and Seasonal Forecasting

Trend-based forecasting accounts for growth or decline over time. Seasonal forecasting focuses on predictable spikes and dips.

Retailers often rely on this method during holidays. Restaurants may use it for weather-related demand changes.

By recognizing trends, small businesses prepare for changes before they occur. As a result, supply planning becomes more accurate.

This approach works best when combined with sales forecasting and market awareness.

Qualitative and Market-Based Forecasting

Qualitative forecasting uses insights beyond numbers. Customer feedback, marketing plans, and industry trends influence predictions.

For new products, historical data may not exist. In these cases, market research guides estimates.

Inventory Forecasting for Small Businesses benefits from blending qualitative insights with quantitative data. This balance improves accuracy.

Owners who stay close to customers gain valuable forecasting signals.

Using Data and Inventory Analytics

Data transforms forecasting from intuition into strategy. Inventory analytics reveal patterns that manual methods often miss.

Sales Data and Forecast Accuracy

Accurate sales data forms the foundation of reliable forecasts. Clean data reflects true demand without distortions.

Point-of-sale systems capture transaction details automatically. This data feeds forecasting models efficiently.

Inventory Forecasting for Small Businesses improves when data updates in real time. Faster insights lead to faster decisions.

Over time, accuracy improves as datasets grow.

Inventory Turnover and Performance Insights

Inventory turnover highlights slow-moving and fast-selling items. Low turnover often signals overstocking or weak demand.

By identifying these items, businesses adjust purchasing strategies. This prevents excess stock buildup.

High turnover products require close monitoring. Forecasting ensures they remain available.

Analytics turn turnover data into actionable planning tools.

Preventing Overstocking Through Analytics

Overstocking ties up cash and storage. Analytics highlight surplus inventory before it becomes costly.

By comparing forecasted demand with actual sales, teams adjust reorder points. As a result, excess inventory declines.

Inventory Forecasting for Small Businesses relies on this feedback loop. Continuous refinement strengthens outcomes.

Smart analytics protect profitability while supporting availability.

Inventory Planning Tools for Small Teams

Modern tools simplify forecasting by automating calculations and visualizing trends. Small teams benefit from accessible technology.

Spreadsheet-Based Planning

Spreadsheets remain common among small businesses. They offer flexibility and low cost.

However, manual updates increase error risk. As data grows, spreadsheets become difficult to manage.

Inventory Forecasting for Small Businesses often outgrows spreadsheets. Automation becomes necessary.

Spreadsheets work best as a starting point.

POS-Based Inventory Forecasting Tools

POS systems integrate sales and inventory data automatically. This integration improves forecast accuracy.

Real-time updates reduce lag between sales and stock adjustments. Managers see current trends instantly.

POS-based tools support demand forecasting inventory workflows efficiently.

This approach saves time and reduces manual errors.

Dedicated Inventory Planning Software

Dedicated tools offer advanced forecasting features. These include predictive analytics and automated alerts.

While powerful, they may require higher investment. Small businesses must weigh cost versus benefit.

Inventory Forecasting for Small Businesses succeeds when tools match operational complexity.

The right software grows alongside the business.

Avoiding Overstocking and Stockouts

Forecasting errors cost money and trust. Understanding common mistakes helps businesses avoid them.

Common Forecasting Pitfalls

Relying on outdated data skews forecasts. Markets change, and assumptions must evolve.

Ignoring lead times also causes issues. Late deliveries disrupt availability.

Inventory Forecasting for Small Businesses improves when assumptions are reviewed regularly.

Continuous monitoring reduces risk.

Balancing Safety Stock and Cash Flow

Safety stock protects against uncertainty. However, excessive buffers tie up cash.

Forecasting helps calculate optimal safety levels. This balance protects service levels.

Smart planning aligns safety stock with demand variability.

Cash flow stability improves as a result.

Adapting Forecasts Over Time

Forecasts are not static. They evolve as new data arrives.

Regular reviews refine accuracy. Teams learn from variances.

Inventory Forecasting for Small Businesses thrives on iteration.

Adaptability ensures long-term success.

How Biyo Helps with Inventory Planning

How Biyo Helps with Inventory Planning

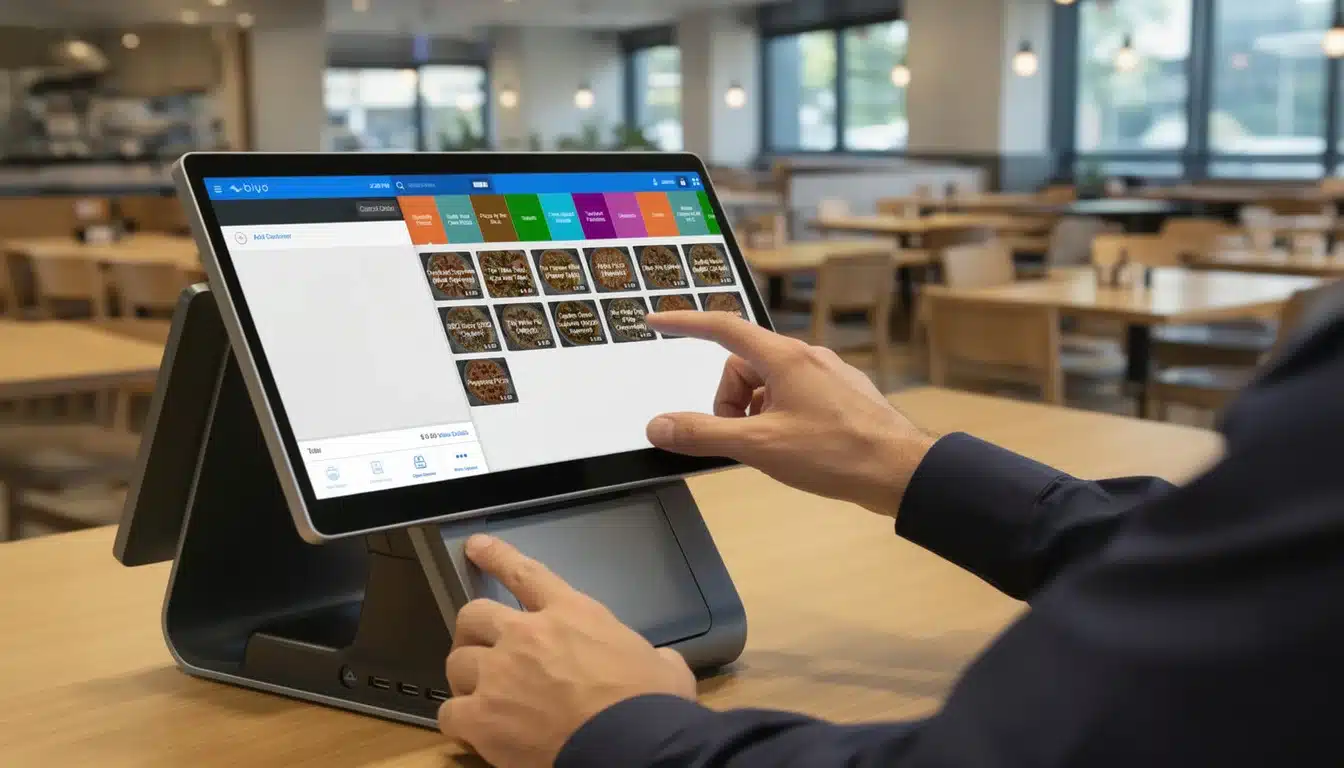

Biyo POS supports inventory forecasting by connecting real-time sales data with inventory tracking. Its reporting and analytics tools help small businesses understand demand patterns and inventory turnover.

With centralized dashboards and flexible inventory management, Biyo simplifies stock planning across locations. Businesses can review trends, adjust reorder points, and make informed purchasing decisions.

To see how Biyo can support inventory forecasting and planning, you can schedule a call or sign up to explore the platform.

Frequently Asked Questions

What is inventory forecasting for small businesses?

It is the process of predicting future inventory needs using sales data, trends, and planning tools to avoid overstocking or shortages.

Why is demand forecasting important?

Demand forecasting inventory methods help businesses align stock levels with customer demand, reducing waste and missed sales.

How often should forecasts be updated?

Most small businesses benefit from monthly reviews, with more frequent updates during seasonal periods.

Do small businesses need advanced forecasting software?

Not always. Many start with POS-based tools and upgrade as operations grow.

How does Biyo POS support inventory forecasting?

Biyo POS provides real-time sales data, inventory analytics, and reporting tools that support accurate forecasting and planning.

Inventory Forecasting Methods That Work

Inventory Forecasting Methods That Work How Biyo Helps with Inventory Planning

How Biyo Helps with Inventory Planning