There’s nothing worse than a long, slow checkout line—it’s a pain for customers and a headache for your team. This is exactly where a POS barcode scanner proves its worth, becoming one of the most important tools in your entire operation. It's so much more than a gadget that beeps; it’s the engine that drives an efficient business, turning a clunky, mistake-prone process into a quick and accurate transaction.

What a POS Barcode Scanner Does for Your Business

At its heart, a point-of-sale (POS) barcode scanner is an input device. It reads the information packed into a barcode and zips it over to your POS system or computer. Think of it as a super-fast translator, instantly converting those black-and-white patterns into useful data like the item's price, description, and stock level.

This one piece of hardware automates a task that used to be incredibly tedious and full of slip-ups. And when you add that automation to your business, the ripple effect is huge.

The Power of Speed and Accuracy

The first thing you’ll notice is the massive jump in checkout speed. Instead of a cashier fumbling to type in a long product code, a quick scan does the job in less than a second. This is how you keep lines moving, make customers happier, and empower your staff to serve more people during those busy rushes.

Accuracy is the other side of that coin. Back in the day, manual entry had an error rate of about one mistake for every 300 characters typed. Barcode scanning slashes that down to roughly one error in 3 million characters—virtually wiping out costly human errors. That kind of precision saves you from pricing mistakes that can eat into your profits or, worse, erode customer trust.

More Than Just Checkout

While faster sales are the main event, a modern POS barcode scanner is a workhorse that does so much more than just ring up items. It becomes central to how you run things behind the scenes.

- Inventory Management: Scanners make receiving new shipments, counting stock, and processing returns incredibly fast and nearly foolproof.

- Customer Engagement: Today’s scanners can easily read QR codes off a customer’s phone, which is perfect for managing digital customer loyalty cards and mobile coupons.

- Data Collection: Every single scan feeds valuable information into your POS system. This gives you a real-time picture of what’s selling, what’s sitting on the shelves, and when you need to reorder.

Bringing a scanner into your setup is a foundational step toward a smarter, more efficient business. To see how it fits into the bigger picture, check out our guide on how to boost sales with a retail POS system with barcode scanners and scales.

How Barcode Scanners Actually Work

Ever wonder what happens in that split second when a scanner zaps a barcode? It’s not magic, but it’s pretty close. Think of a POS barcode scanner as a super-fast translator. It beams a light onto the barcode, instantly reads the pattern of reflected light—the unique sequence of thick and thin lines or tiny squares—and translates that visual code into digital information your point-of-sale can understand.

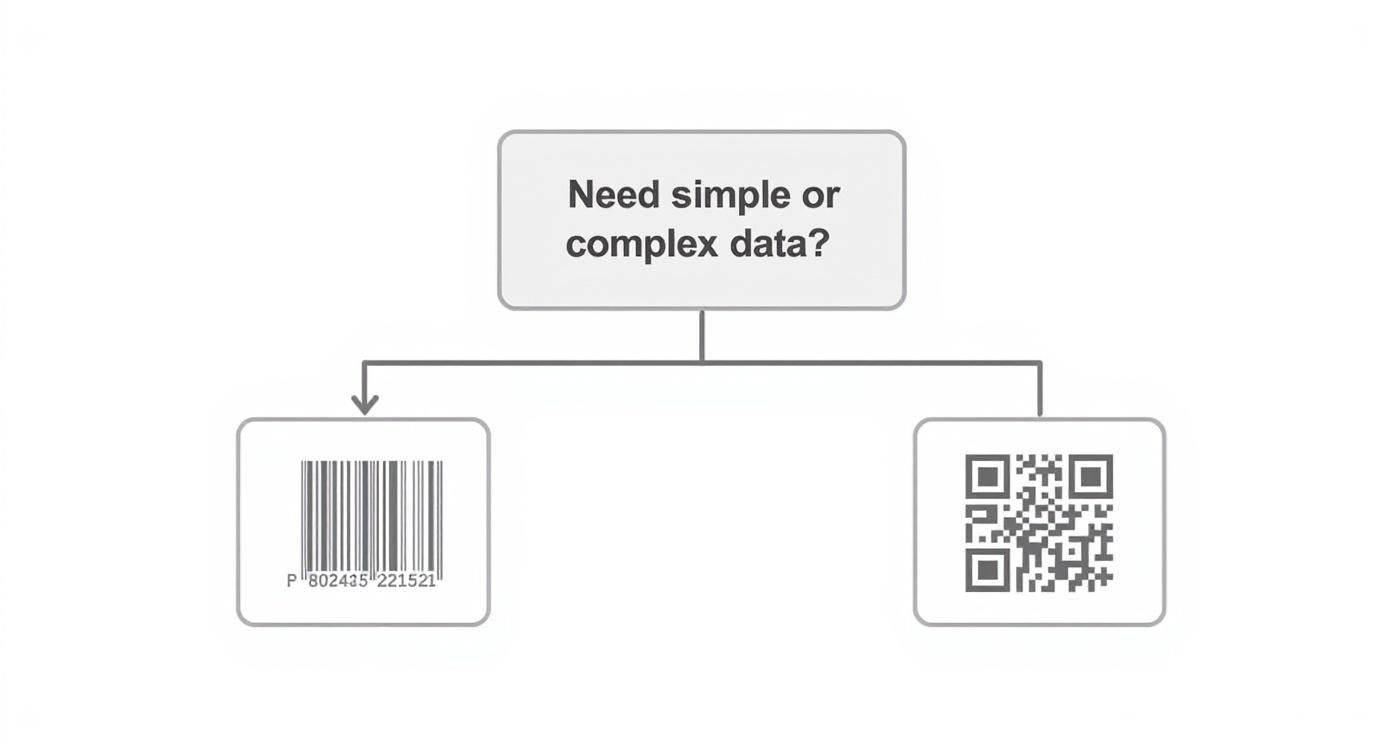

To pick the right scanner, you first need to understand the two main "languages" they speak: 1D and 2D barcodes. Getting a handle on this difference is the most important step in finding the right tool for your business.

The Two Families of Barcodes: 1D and 2D

The core distinction between barcode types is how they store information. One is a simple ID tag; the other is a full-blown data packet. Each is designed for a completely different job.

Here's a simple way to think about it: A 1D barcode is like a license plate. It's just a unique number that your system has to look up in a database to get the details (price, product name, etc.). A 2D barcode is more like a complete driver's license—it holds all the important information right there on the card.

This fundamental difference has a huge impact on what you can do at the checkout counter and in your marketing efforts.

H3: 1D Barcodes: The Classic Lines

One-dimensional, or 1D, barcodes are the old-school vertical stripes we've all seen a million times on groceries and retail products. You might also hear them called linear barcodes.

- What they look like: A straight line of parallel black bars and white spaces, each with a different width.

- What they hold: A pretty small amount of simple, text-based data. Usually, this is just the product’s UPC or another identification number.

- What they’re for: They are the workhorses of traditional retail. Perfect for ringing up products, taking inventory, and tracking assets where all you need to do is quickly identify an item.

If your main job is simply scanning pre-cataloged items from your shelves, a basic 1D scanner will get the job done reliably.

H3: 2D Barcodes: The Modern Squares

Two-dimensional, or 2D, barcodes are the newer, block-like codes you see everywhere now, with QR codes being the most famous example. They store data both horizontally and vertically, which is a game-changer.

- What they look like: A matrix of small squares, dots, or even hexagons.

- What they hold: A ton of data. We're talking thousands of characters, which can include website links, photos, promotional details, and contact info.

- What they’re for: They're essential for modern business. Think mobile payments, digital loyalty cards, online tickets, and scanning coupons right off a customer's phone screen.

If you want to run promotions with QR codes or let customers pay with an app, a POS barcode scanner that can read 2D codes is non-negotiable.

H3: Why This Difference Matters for Your Business

So, do you need a scanner that only reads 1D barcodes, or one that handles both? It really boils down to how you operate. A small hardware store just selling physical inventory might be perfectly happy with a 1D scanner. But a bustling café that takes mobile payments, offers a digital loyalty program, and runs QR code campaigns absolutely needs a 2D imager.

Making the right choice now helps future-proof your setup. As customer interactions and marketing become more digital, having the ability to read 2D barcodes opens up a whole new world of possibilities for connecting with customers and making your workflow smoother.

To make it even clearer, here’s a quick rundown of how the two stack up.

1D vs. 2D Barcodes: A Quick Comparison

This table compares the key characteristics of 1D and 2D barcodes to help businesses decide which technology best suits their operational needs.

| Feature | 1D Barcodes (Linear) | 2D Barcodes (Matrix) |

|---|---|---|

| Appearance | A series of vertical black and white lines | A pattern of squares, dots, or hexagons |

| Data Storage | Low (around 20-25 characters) | High (over 2,000 characters) |

| Data Type | Alphanumeric only | Text, URLs, images, and other binary data |

| Primary Use | Product identification at checkout | Marketing, mobile payments, ticketing, loyalty |

| Best For | Standard retail, inventory, asset tracking | Interactive customer engagement, digital coupons |

Ultimately, while 1D barcodes are great for managing what's on your shelves, 2D barcodes are all about engaging with the customer holding their phone in their hand.

Finding the Right Scanner Shape and Connection

Once you know what kind of barcode you’ll be scanning (the simple 1D stripes or the more complex 2D squares), it's time to think about the hardware itself. The perfect POS barcode scanner should feel like a natural part of your checkout flow, not a clunky gadget that gets in the way.

We're going to look at the physical designs—what we call form factors—and how they connect to your system. Getting this combination right can make a huge difference. What works for a bustling supermarket checkout would be overkill for a cozy boutique, and a boutique's nimble scanner would get overwhelmed in a grocery store. It’s all about matching the tool to the task.

Choosing the Right Form Factor

How will your staff actually use the scanner every day? That's the core question. The shape of the device dictates the workflow. Are your employees always at a fixed counter, or do they need to move around the shop floor?

- Handheld Scanners: These are the jack-of-all-trades and what most people picture. They can be corded or wireless, and you simply pick them up, aim, and shoot. Think of a retail clerk scanning a heavy winter coat that's too bulky to lift onto the counter—a handheld scanner makes it effortless.

- Presentation Scanners: These are the hands-free heroes. They sit on the counter, and you just pass items over the scanning window. They’re fantastic for high-speed environments like coffee shops or busy delis where employees need both hands free to pack orders and handle payments.

- In-Counter Scanners: Built right into the checkout lane, these are the heavy-lifters you see in grocery stores and big-box retailers. They offer the absolute fastest scanning experience, letting cashiers slide items across the surface without missing a beat.

This flowchart gives you a quick visual on how the type of data you use points you toward either a simple 1D barcode or a more advanced 2D code.

As you can see, if you just need to identify a product, a 1D barcode is your go-to. But for richer information, like linking to a website or applying a digital coupon, you'll need a 2D code.

Connecting Your Scanner to Your System

How the scanner "talks" to your POS terminal is just as important as its shape. Your connection choice affects everything from employee mobility to how tidy your counter looks. Each option has its own clear pros and cons.

Think of it like a landline versus a cellphone. The landline (a wired scanner) is dead reliable and always where you expect it to be, but you’re tethered to the wall. The cellphone (a wireless scanner) gives you total freedom, but you have to keep it charged and stay in a service area.

Let’s dig into the most common ways to get your scanner hooked up.

Wired USB Scanners

A wired USB barcode scanner is the definition of plug-and-play. It gets its power and sends its data through a single cable plugged straight into your POS terminal. Simple and effective.

- Pros: Rock-solid reliability with zero signal interference. No batteries to worry about. They're also typically the most budget-friendly option.

- Cons: The cord limits your movement and can add to counter clutter.

- Best For: Any fixed checkout station, like in a retail shop, a cafe, or any spot where the scanner doesn't need to stray from the register.

Wireless Bluetooth Scanners

A Bluetooth scanner cuts the cord, giving you the freedom to roam. For many businesses, this mobility is a complete game-changer.

- Pros: Total freedom to move around, usually with a range of 30 feet or more. This lets staff scan heavy items left in the shopping cart, do quick inventory checks in the aisle, or even manage curbside pickup orders.

- Cons: You have to remember to charge them. They also tend to cost a bit more than their wired counterparts.

- Best For: Restaurants using tableside ordering, retailers looking to "line-bust" during a rush, and warehouses that need to manage stock on the shelves.

For nimble businesses like small cafes, pairing a wireless scanner with a tablet-based POS creates an incredibly flexible and powerful setup. You can dive deeper into this topic in our guide on the best affordable tablet POS for small cafes with offline mode.

By thinking through both the form factor and the connection type, you can land on a POS barcode scanner that doesn't just work—it actively makes your day-to-day operations run smoother for your staff and your customers.

Picking a Scanner That Can Keep Up: Performance and Durability

Once you've settled on the right shape and connection type, it's time to look under the hood. The internal tech of a POS barcode scanner is what separates a trusty workhorse from a device that causes daily headaches. To find something that will truly last, you have to push past the flashy marketing claims and zero in on the specs that actually affect speed, accuracy, and longevity.

Let's dig into the performance indicators that really matter when you're in the trenches, starting with how fast it scans and what it does with less-than-perfect barcodes.

Can It Handle the Pressure? Speed and Accuracy

In a busy shop or a slammed restaurant, every single second counts. A scanner that hesitates or misreads can be the single point of failure that creates long lines and ticks off customers. That’s why you have to think about performance in real-world terms.

-

Scan Speed (Scans Per Second): Manufacturers love to tout this number, which tells you how many times a scanner tries to read a barcode in one second. But a high number is meaningless if it fails on the first pass. What you're really looking for is first-read accuracy—how often it nails the scan on the very first try. For most businesses, a scanner with rock-solid first-read accuracy is far more valuable than one with a ridiculously high (and often impractical) scan rate.

-

Decode Capability: This might be the most important feature of all. Think of it as the scanner's ability to read messy handwriting. Decode capability is how well a scanner can read barcodes that are smudged, poorly printed, faded, torn, or wrapped in plastic. A scanner with weak decoding skills will constantly stumble, forcing your staff to punch in numbers manually and bringing the whole checkout process to a grinding halt. A quality POS barcode scanner with advanced decoding technology keeps things moving smoothly, no matter how beat-up the label is.

A scanner with great decode capability is your best insurance policy against checkout delays. It prevents that awkward pause while a cashier fumbles with a wrinkled package, keeping the line flowing and customers happy.

Is It Built to Last? Finding a Tough-Enough Scanner

Durability isn't just a nice-to-have feature; it's a must, especially if the scanner will live in a hectic kitchen, a dusty warehouse, or a high-traffic retail counter. Scanners get dropped, bumped, and splashed on. A cheap, consumer-grade device just isn't going to cut it.

This is where you need to look for industrial ratings. These standardized specs give you a clear, no-nonsense measure of how tough a scanner really is.

Making Sense of Durability Ratings

Two key numbers tell you almost everything you need to know about a scanner's ability to take a beating: its drop spec and its IP rating.

-

Drop Specification: This tells you how high the scanner can be dropped onto a hard surface (usually concrete) before it's likely to break. Look for a rating like "multiple 6-foot drops to concrete"—that’s a good sign it has a rugged build. Some models also list a "tumble" spec, which simulates hundreds of smaller, repeated tumbles to mimic everyday clumsiness.

-

IP Rating (Ingress Protection): This simple two-digit code rates how well a device is sealed against solids (like dust) and liquids (like water). The first number is for solids (0-6) and the second is for liquids (0-9). For instance, an IP54 rating means the scanner is well-protected from dust and can handle splashes from any direction. That's a solid choice for most restaurant and retail jobs.

Spending a bit more on a durable scanner from the get-go will save you a ton of money on replacements and prevent the high cost of downtime. This focus on reliability is a big reason why the barcode scanner industry is projected to hit USD 15.8 billion by 2035. And it's no surprise that around 70% of that market is made up of portable handheld models, which businesses choose specifically for their blend of flexibility and tough design. Learn more about these barcode scanner market trends.

By paying close attention to these performance and durability features, you can choose a POS barcode scanner that not only solves your immediate problems but also proves to be a smart, reliable investment for years to come.

Integrating Your Scanner with Your POS System

Even the best POS barcode scanner on the market is useless if it can't talk to your point-of-sale software. When the two don't communicate perfectly, you’re left with a fancy paperweight and a frustrated team. Getting the integration right isn't just a technical checkbox; it’s what turns a powerful tool into a genuine efficiency boost for your business.

The good news is that this process is usually straightforward, especially with modern systems built for easy, out-of-the-box setup. By focusing on a few key areas—compatibility, pairing, and configuration—you can make sure your new scanner works like a charm from the very first scan.

First Things First: Check for Compatibility

Before you even think about plugging anything in, the absolute first step is confirming your new scanner will work with your current setup. This simple check can save you a world of headaches down the road. It’s like making sure you have the right key before you try to unlock the door.

Start by looking at the operating system (OS) and any driver requirements. Most scanners today are built to work with the big players like Windows, macOS, iOS, and Android, but it never hurts to be sure.

- Operating System (OS): What OS does your POS terminal run on? Head over to the scanner's product page or manual and make sure your specific version is supported.

- Driver Support: Many new USB scanners are "plug-and-play," which means your system recognizes them automatically without any extra software. Some more advanced or specialized models, however, might need a driver. It's crucial to know which kind you have.

A quick compatibility check is your best friend for a stress-free setup. Taking five minutes to confirm the OS and driver needs can prevent a failed integration and the hassle of a return.

Pairing Your Scanner: The Simple Steps

Once you've confirmed compatibility, you're ready to connect your device. The process is a little different depending on whether you've got a wired USB model or a wireless Bluetooth scanner.

For a Wired USB Scanner:

This is about as easy as it gets.

- Make sure your POS terminal is on and the software is open.

- Plug the scanner’s USB cable directly into an open USB port on your POS device.

- Give it a few seconds. Your system should recognize the new hardware, usually with a small notification pop-up or a chime.

- To test it, open a text field in your POS or even a simple notepad and scan a barcode. The numbers should pop up instantly.

For a Wireless Bluetooth Scanner:

This just involves a quick pairing process, a lot like connecting wireless headphones to your phone.

- Ensure the scanner is fully charged and powered on.

- Put the scanner into "pairing mode." You usually do this by holding down a button or scanning a special barcode you'll find in the user manual.

- On your POS terminal or tablet, go to the Bluetooth settings and search for new devices.

- Select your scanner from the list—it will often show up with a model name like "Honeywell Voyager" or a generic ID—and you’re paired.

Offline Behavior and Final Tweaks

A crucial feature people often forget about is how the scanner works when the internet goes down. For any business that can't afford to stop making sales, this is a big deal. A quality POS barcode scanner paired with an offline-capable system means you can keep scanning items and ringing up customers. The sales data simply syncs up once you're back online.

Finally, take a moment to poke around in your POS software settings. Most systems let you tweak how the scanner behaves, like adding a prefix or suffix to every scan or setting up specific workflows for certain items. Spending a little time here helps tailor the scanner's performance to your exact business needs. It’s all part of a bigger picture, and understanding how a POS system works can help you see how all the pieces, including your new scanner, fit together.

Scanner Maintenance and Troubleshooting Tips

Your POS barcode scanner is a workhorse. It gets handled constantly, every single day. To keep it scanning reliably and avoid that dreaded moment when it stops working mid-rush, a little proactive care is all it takes. Think of it as an insurance policy for your checkout line—a few simple checks can prevent most headaches before they even start.

Consistent maintenance not only keeps your operations running smoothly but also helps you get the most out of your investment by extending the scanner's lifespan.

A Practical Maintenance Checklist

You don’t need to be a tech wizard to keep your scanner in peak condition. Just build these quick tasks into your daily or weekly closing routine.

- Clean the Scanner Window: This is the big one. Dust, smudges, and fingerprints on the scanner’s lens are the top culprit for failed reads. A gentle wipe with a soft, lint-free microfiber cloth is usually all it needs to see clearly again.

- Inspect All Cables: For corded scanners, give the USB cable a quick look-over. Pay close attention to the connection points, checking for any signs of pinching, fraying, or other damage that could lead to a spotty connection.

- Check Battery Contacts: If you’re using a wireless model, pop the battery out every so often and check the contacts inside the scanner and on the charging base. Keeping them clean and free of grime ensures it gets a solid charge every time.

Solving Common Scanner Problems

Even with the best care, glitches can happen. Before you spend time on a support call, try these quick diagnostic steps. More often than not, they’ll get you back up and running in minutes.

Issue 1: Scanner Won't Connect or Power On

- For Wired Scanners: The classic "turn it off and on again" works wonders here. Unplug the USB cable, wait a few seconds, and plug it back into a different USB port on your POS terminal. This often resolves simple connection hiccups.

- For Wireless Scanners: First, confirm the scanner is actually charged and that its base is plugged in and has power. If it’s still not connecting, try re-pairing it with your POS by following the Bluetooth setup instructions in the manual.

Issue 2: Scanner Misreads Barcodes or Scans Twice

This one feels like a hardware problem, but it's usually software. A double scan or a garbled entry often points to a conflicting setting in your POS system. Dive into the settings and look for any "keyboard shortcuts" or automated commands that might be interfering with the scanner’s input. You can also reset the scanner to its factory defaults—your user manual will have a special barcode to scan that clears out any faulty configurations.

Maintaining your equipment is more than a chore; it’s about protecting your investment and keeping your business humming. With the global barcode scanner market projected to grow from USD 7.4 billion to USD 13.0 billion by 2033, our reliance on these crucial tools is only getting stronger. Discover more insights about the barcode scanner market on imarcgroup.com.

Security and Compliance Considerations

Finally, remember that maintenance isn't just about the physical device—it's also about its digital health. Your scanner is an entry point for data, which makes its security a vital part of protecting your entire business.

Make it a habit to check the manufacturer’s website for firmware updates. These updates often include important security patches that plug vulnerabilities. And since your scanner handles product and payment data, its proper function is directly linked to your PCI compliance. Keeping your scanner and POS system secure is a non-negotiable step in safeguarding customer information and protecting your business from costly data breaches.

Your Top Questions About POS Barcode Scanners, Answered

Picking out a POS barcode scanner can bring up a lot of questions. It’s a crucial piece of gear, and getting it right from the start saves a ton of headaches down the road. Let's tackle some of the most common things business owners ask.

One of the first thoughts many people have is, "Can't I just use my phone?" It’s a fair question. While phone camera apps can technically read a barcode, they just aren't cut out for a real-world checkout environment. A dedicated scanner is built for speed, durability, and pure repetition in a way a smartphone can't ever be. Think instant reads, drop-proof designs, and an ergonomic feel made for all-day use.

Budgeting and Tech Decisions

So, what about the price tag? How much should you really be spending on a scanner? The cost really depends on what you need it to do and how tough you need it to be.

- Entry-Level 1D Scanners: You can get a basic, wired 1D scanner for simple retail items for as little as $100.

- Durable 2D Scanners: If you need something rugged, wireless, and capable of reading barcodes from screens, you'll be looking at anywhere from $350 to over $500.

My advice? Don't think of it as just another expense. See it as an investment in your own efficiency. A little extra spent on a tough, 2D-capable scanner usually pays you back quickly in saved time, fewer frustrations, and the ability to run modern promotions like QR code discounts.

Finally, you'll hear terms like "laser" and "imager" thrown around. What's the actual difference? A traditional laser scanner casts that familiar thin red line. It's perfectly fine for reading standard 1D barcodes on a product label, but it falls short when trying to read anything from a digital screen.

An imager, however, is basically a tiny camera. It snaps a picture of the barcode, which allows it to decipher both 1D and 2D codes from virtually any surface—including your customer’s smartphone. For any modern business running digital coupons, loyalty programs, or event tickets, an imager isn't just a nice-to-have; it's essential.

Ready to pair the perfect scanner with a powerful POS system? Biyo POS seamlessly integrates with leading hardware to streamline your checkout, manage inventory, and grow your business. See how our all-in-one solution can work for you at https://biyopos.com.