Restaurant supply chain management is all about making sure your kitchen gets the right ingredients at the right moment—without overspending or sacrificing quality. It brings together sourcing, logistics, storage, and inventory control into one smooth-running operation.

Tracing The Restaurant Supply Chain Journey

Think of your supply chain as the backstage crew in a Broadway production. Diners only see the final dish, but every unseen move—from farm to fork—must be perfectly timed.

This starts at the farm and ends at your kitchen door.

- Procurement selects top-notch ingredients from trusted producers.

- Logistics coordinates transport under exacting conditions.

- Storage preserves freshness through the right temperature settings.

- Inventory Control monitors real-time stock to avoid waste and shortages.

Each step hands off smoothly, much like a relay race, and mastering them is the first step to supply chain success.

Key Stages Explained

Procurement is more than buying in bulk—it’s choosing suppliers that balance cost, consistency, and quality. A few dollars saved on poor produce can cost your reputation in the long run.

Logistics covers everything from shipping schedules to vehicle temperature controls. A delayed delivery of dairy or produce can throw your entire service off track.

Behind every great restaurant is a supply chain tuned like a finely oiled machine.

Storage isn’t just a walk-in fridge. It includes humidity controls, organized shelving, and clear labeling to keep flavors locked in and waste out.

Inventory control closes the loop by tracking usage rates, setting reorder alerts, and flagging potential shortages before they hit.

Farm-To-Fork In Action

Picture a head of lettuce: it’s harvested at dawn, chilled in transit, then arrives at your kitchen just in time for service. Every handoff needs clear communication and precise timing.

- Farm pickup within hours of harvest to lock in peak freshness.

- Temperature-controlled transport with digital logging.

- Time-stamped receiving at your restaurant door.

- Real-time POS updates that flag low stock automatically.

This chain of custody shows how each link depends on the last—and why optimizing every handoff keeps quality high and delays low.

Why Supply Chain Matters

A strong supply chain can cut food costs by up to 15 percent through smarter purchasing and less spoilage. It also guarantees that your signature dishes taste the same night after night.

- Cost savings from bulk orders and tighter waste controls

- Enhanced guest loyalty with consistent menu items

- Better resilience when suppliers or markets fluctuate

Treating your supply chain as a strategic asset turns behind-the-scenes logistics into a clear advantage.

Real-World Example

Bella’s Bistro sources heirloom tomatoes from a nearby farm. When an unexpected late frost halved the crop, backup contracts and instant stock alerts kept those dishes on the menu.

This scenario proves how diversified sourcing and proactive monitoring stop surprises from derailing your service.

Next, we’ll dive into each pillar—sourcing, logistics, storage, and inventory—with hands-on tactics you can put into practice today.

The Pillars of a Modern Restaurant Supply Chain

Every great restaurant runs on a network that brings ingredients from the farm to the fork. This network, your supply chain, has four essential functions that work together to keep your kitchen humming and your customers happy.

Think of it like the foundation of a house. If one part is weak, the whole structure is at risk. A crack in your sourcing can lead to inconsistent dishes, while a problem with logistics might mean you run out of your star ingredient on a busy Friday night.

Let’s break down how it all connects, from suppliers to your back door.

This simple flow shows the journey: from Suppliers (the growers and producers) to Distributors (the logistics pros who consolidate and deliver), and finally to your Restaurant. Each step is a critical link.

Sourcing and Procurement

This is where it all begins: finding the right partners and striking the right deals. Great sourcing isn’t just about finding the cheapest price; it’s about building relationships with reliable suppliers who can deliver consistent quality. This is what keeps your signature dish tasting the same every single time.

Of course, it’s not always smooth sailing. You’ll face challenges like supplier reliability, unpredictable price swings, and frustrating minimum order requirements. Staying on top of a few key metrics can help you spot trouble early.

A few numbers to watch:

- Lead Time: The average number of days it takes from placing an order to getting it delivered.

- Cost Variance: How much your actual ingredient costs differ from what you budgeted.

- Fill Rate: The percentage of your order that arrives correctly, without any missing items or substitutions.

- Supplier Score: A simple rating you create to track who delivers on time and with the right quality.

Logistics and Delivery

Once you’ve ordered your ingredients, they need to get to you safely and on time. This is logistics in a nutshell—the art and science of moving goods from point A to point B under the right conditions.

Things can go wrong here. Transit delays can throw off your prep schedule, a broken refrigerator on a truck can ruin an entire shipment of produce, and inefficient delivery routes can drive up costs.

To keep your deliveries dependable, keep an eye on these data points:

- On-Time Delivery Rate: What percentage of shipments show up when they’re supposed to?

- Temperature Compliance: For refrigerated or frozen goods, what percentage of the delivery stayed within the safe temperature zone?

- Cost Per Mile: A useful metric for understanding how much transportation is really costing you.

- Delivery Variance: How often do deliveries deviate from their planned schedule?

To see how these moving parts fit together, let’s look at the entire journey. The table below outlines the goals and common roadblocks at each major step of the supply chain.

Key Stages of the Restaurant Supply Chain

| Stage | Primary Goal | Common Risks & Challenges |

|---|---|---|

| Sourcing & Procurement | Secure consistent quality ingredients at an optimal cost. | Supplier delays, price spikes, order minimums, quality issues. |

| Logistics & Delivery | Transport goods on time while preserving safety and quality. | Transit delays, temperature breaches, routing hiccups, damaged goods. |

| Storage & Warehousing | Preserve freshness and prevent spoilage with proper handling. | Insufficient space, temperature variability, mislabeling, cross-contamination. |

| Inventory Control | Maintain optimal stock levels to minimize waste and avoid shortages. | Overstocking, stockouts, inaccurate forecasting, theft, and spoilage. |

Each stage presents its own set of challenges, but with a clear goal in mind, you can build systems to manage them effectively.

Storage and Warehousing

Your ingredients have arrived—now what? Proper storage is all about preserving that quality you paid for. This means precise temperature and humidity controls in your walk-in coolers, freezers, and dry storage areas.

The biggest headaches here are often equipment failures (a freezer dying overnight), not having enough space, or simply poor organization leading to misplaced items.

These metrics will tell you if your storage is working as it should:

- Temperature Deviation: How much do your cooler or freezer temperatures fluctuate from their set points?

- Storage Utilization: What percentage of your available storage space is actually being used?

- Shrinkage Rate: How much inventory are you losing to spoilage, waste, or theft while it’s in storage?

Inventory Control

Finally, we get to inventory control: the delicate balancing act between having enough on hand to meet demand and not so much that it goes to waste. Good inventory management prevents the dreaded “86” on your menu and keeps food costs in check.

The main culprits of poor inventory control are inaccurate sales forecasts, tedious and infrequent manual counts, and information being stuck in different systems that don’t talk to each other.

Real-time tracking is your best friend here. Focus on these indicators:

- Turnover Rate: How quickly are you selling through your entire stock of an item?

- Stockout Frequency: How often do you run out of a critical ingredient?

- Dead Stock: The value of inventory that’s just sitting on the shelf, not being used.

“Consistent metrics across these pillars turn data into a competitive advantage. You stop guessing and start knowing.” — Operations Manager, 15 years in food service.

By keeping a close watch on these numbers, you bring clarity and stability to your supply chain, making it much easier to manage and grow.

Connecting the Pillars to Performance

When all four pillars are strong and working together, your back-of-house runs like a well-oiled machine. You avoid last-minute scrambles for ingredients and stop throwing money in the trash from spoiled food.

Not sure where to start? Try these quick health checks:

- Are your top suppliers meeting a 90% on-time delivery benchmark?

- Are your walk-in coolers holding steady, with temperature deviations under 2°F?

- Are you hitting an inventory turnover goal of around 8 cycles per month for key items?

Addressing small issues like these can strengthen your entire operation. Use these pillars as a guide when you’re thinking about a new supplier or a different delivery service. Finding the right balance across sourcing, logistics, storage, and inventory is what transforms your supply chain from a daily headache into a powerful engine for success.

Why a Strong Supply Chain Is Your Competitive Edge

When your back-of-house runs like a well-oiled machine, it shows on the plate—and your bottom line. Tight control over sourcing and delivery doesn’t just keep costs in check; it builds a reputation for reliability.

In fact, precise cost tracking can slash food expenses by 15 percent, while consistent ingredient quality keeps guests coming back night after night.

- Rock-Solid Cost Control that safeguards profit margins and cuts waste

- Uniform Ingredient Standards to ensure every dish meets expectations

- Improved Customer Loyalty by preventing menu outages

- Operational Resilience to ride out sudden disruptions

- Fewer Rush Purchases and surprise fees from emergency orders

Real Savings In Action

A mid-sized bistro negotiated bulk purchases and watched annual food costs drop by 12 percent. That extra budget went straight into testing creative specials—without ever compromising on quality.

| Metric | Before | After |

|---|---|---|

| Food Cost % | 33% | 21% |

| Inventory Shrinkage | 8% | 3% |

| On-Time Delivery | 88% | 96% |

This simple side-by-side highlights what smarter buying can achieve.

Real World Impact Of Efficiency

Picture a fully booked Friday night: orders streaming in, kitchen humming, and no frantic calls to suppliers. Automated alerts ping managers when stock dips below critical levels, so dishes never stall—and staff stay focused on service.

“Consistent supply chain metrics turn unpredictability into confidence,” shares a veteran restaurant operations director.

Still, keeping that rhythm as you grow is the real test. The global food service market stood at $3.5 trillion and is on track to hit $6.8 trillion by 2032, growing at a CAGR of 7.79% from 2025 to 2032. This surge only raises the stakes for solid supply chain management. Read the full research on the global food service market on Fortune Business Insights.

Benefits Beyond Savings

A lean supply chain doesn’t just protect your margins—it strengthens your brand and keeps guests happy. When you’re prepared for sudden price spikes or shortages, you:

- Delight diners by keeping signature dishes on the menu

- Cut emergency purchase costs with pre-negotiated rates

- Uphold your reputation through consistent quality

- Mitigate risk by lining up backup suppliers and clear reorder points

Investing in supply chain mastery is investing in long-term success.

On top of cost savings, a finely tuned system reduces spoilage and waste—an eco-plus guests notice and appreciate.

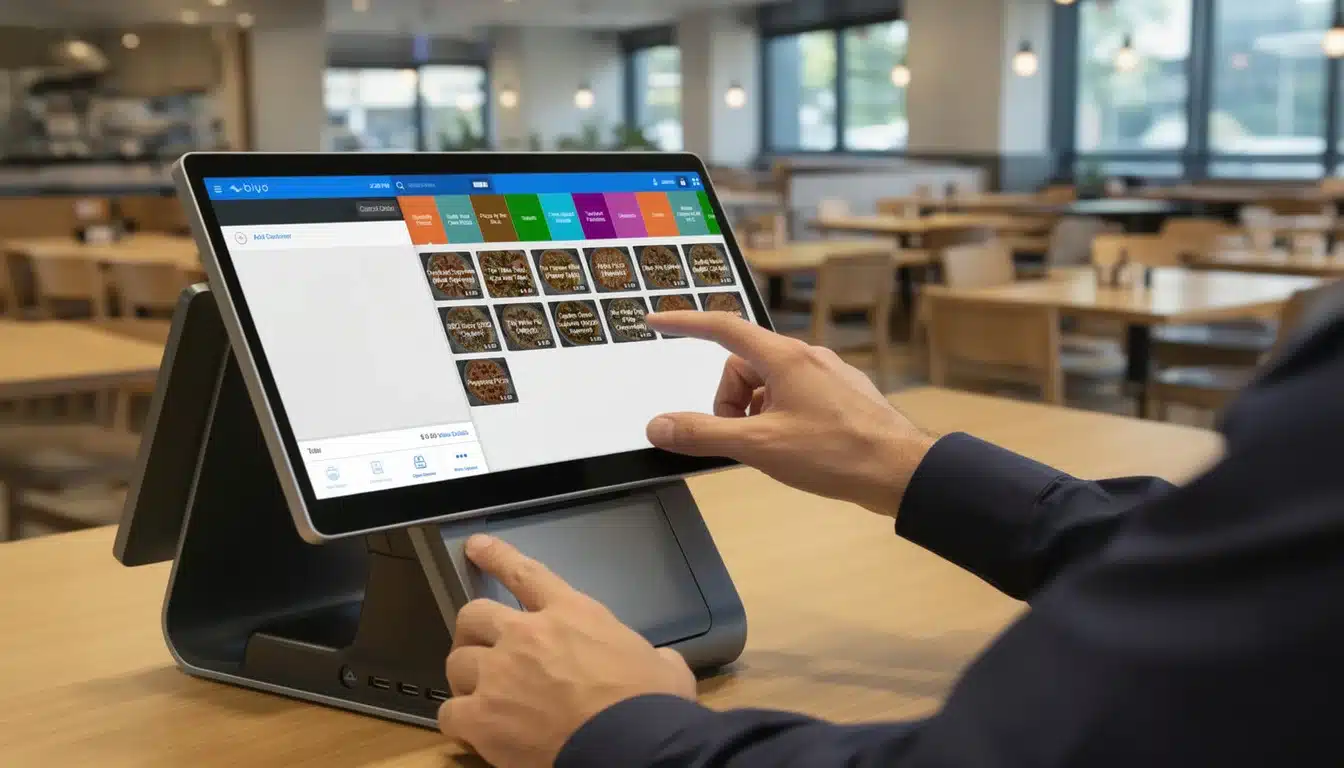

Integrating your real-time POS data and inventory controls, for example with Biyo POS, unlocks these advantages. Orders fire off automatically when stock nears reorder levels, and managers get instant updates on supplier performance.

When storms, transport delays or global hiccups strike, pre-arranged agreements keep the kitchen running without a hitch.

With a robust supply chain underpinning every shift, your restaurant stands out—even in the busiest neighborhoods. Track metrics like waste reduction and on-time delivery to measure—and showcase—your competitive edge.

Navigating Common Supply Chain Hurdles

Even the most buttoned-up restaurant supply chain will hit some turbulence. From sudden price spikes to a supplier who just can’t seem to show up on time, these headaches can derail your kitchen, inflate food costs, and ultimately sour the guest experience. Getting a handle on these common pain points is the first step toward building an operation that can roll with the punches.

Imagine planning your weekly specials around beautiful, fresh avocados, only to find the price has doubled overnight because of a transportation strike hundreds of miles away. Or picture a slammed Saturday night when your dairy delivery is a no-show, forcing you to “86” half your dessert menu. These aren’t just hypotheticals—they’re the day-to-day reality of managing a restaurant’s supply line.

Every disruption is a direct threat to your profitability and your reputation. By pinpointing where your operation is most vulnerable, you can start turning these frustrating challenges into smart opportunities for improvement.

The Challenge of Price Volatility

Few things can torpedo a restaurant’s budget faster than the rollercoaster of ingredient costs. A freak cold snap can send lettuce prices through the roof, while global events can jack up the price of imported goods like olive oil or coffee beans. Without a solid plan, these swings take a direct bite out of your margins.

This kind of volatility turns menu pricing into a constant guessing game. Cost stability is the bedrock of a healthy restaurant, and when your ingredient costs are all over the map, it’s nearly impossible to keep your finances on solid ground.

“Managing a restaurant supply chain is like navigating a ship in a storm. You can’t control the weather, but you can build a more robust vessel and chart a smarter course to avoid the worst of it.”

To fight back, savvy operators build flexibility into their purchasing strategy. This might mean locking in longer-term fixed pricing with key suppliers for your most-used items or designing menus around ingredients that aren’t so prone to wild price swings. The goal is to create a buffer that can absorb market shocks.

Unreliable Suppliers and Quality Issues

Another huge hurdle is simply dealing with inconsistent suppliers. A vendor who frequently misses delivery windows, short-ships an order, or sends you produce that’s seen better days can throw your entire service into chaos. A truck that’s an hour late can stall prep work, leading directly to longer ticket times during a busy dinner rush.

Even worse is getting a case of tomatoes that are bruised and mealy. Now you have a choice: reject the order and scramble for a last-minute replacement, or serve a dish that doesn’t live up to your standards. These aren’t just one-off problems; they slowly erode the trust you have with your suppliers, making it tough to build the kind of strong partnerships you need to succeed.

The Hidden Costs of Supply Chain Gaps

Supply chain hiccups create more than just immediate fires to put out—they send ripples across your entire business. Globally, it’s estimated that a staggering 13.2% of all food produced is lost somewhere between the farm and the consumer. That loss impacts everything from ingredient availability to the final price on your invoice, making it a constant battle to fulfill your menu efficiently. You can learn more about these restaurant supply chain disruptions to see the full picture.

These problems often get magnified during your busiest seasons when demand is at its peak. Ingredient shortages and delivery delays can mean lost sales and, even more damaging, unhappy customers. When a guest can’t order their favorite dish, it puts a stain on their entire dining experience. This is where strengthening your supplier relationships and using historical sales data to forecast better become critical. It’s how you navigate this fragile system, cut down on waste, and protect your bottom line.

Actionable Strategies to Optimize Your Supply Chain

Building a smarter, more resilient supply chain isn’t about one big, dramatic change. It’s about targeting key areas with proven tactics that turn raw data into smart decisions and transform frantic orders into on-time deliveries.

Ready to get started? Focus on these four pillars:

- Cultivate Strong Supplier Partnerships: Treat them like true partners, not just vendors.

- Master First-In-First-Out (FIFO): This is your secret weapon against spoilage.

- Forecast Demand Accurately: Use your POS insights to predict what you’ll need.

- Diversify Your Supply Network: Don’t put all your eggs in one basket.

Let’s break down what each of these looks like in the real world.

Cultivating Strong Supplier Partnerships

Your suppliers are an extension of your team. When you treat them that way, everything changes.

Shift your mindset from transactional to collaborative. Open, honest conversations about volume discounts, quality standards, and delivery windows build trust and eliminate those frustrating last-minute surprises.

“Great supplier relationships can cut emergency orders by 40%, freeing up both your time and your budget.”

Schedule regular check-ins and joint planning sessions. It helps both sides get aligned for peak seasons, new menu launches, and any unexpected bumps in the road.

Mastering FIFO to Slash Spoilage

FIFO, or First-In-First-Out, is a simple concept with a massive impact. It’s the golden rule for ensuring older stock gets used first, which directly minimizes waste and keeps your food costs in check.

Getting it right is easier than you think:

- Label everything. As soon as stock comes in, label it with a clear “received” date.

- Organize your shelves. Always place the oldest items at the front and new arrivals in the back.

- Train your team. Make stock rotation a non-negotiable part of every shift change.

This simple discipline means fewer expired items tossed in the trash and far more consistent, predictable food costs.

Smart Demand Forecasting With POS Data

Guesswork is expensive. Accurate forecasting, on the other hand, starts with the real sales figures you already have.

Your Biyo POS is a goldmine of information. Dig into the reports to identify sales patterns, not just day-to-day but week-to-week and season-to-season. Tracking which dishes are selling and when they’re popular allows you to adjust your orders before you’re staring at an empty shelf.

Building a Resilient Supplier Network

Relying on a single source for a critical ingredient is a huge risk. Diversifying your suppliers is your insurance policy against local shortages, weather events, and sudden price hikes.

Consider taking these steps to build a more robust network:

- Partner with multiple local growers or regional distributors for key ingredients.

- Invest in relationships with temperature-controlled carriers to guarantee freshness on arrival.

- For larger operations, integrating your ERP with a Transportation Management System (TMS) provides incredible end-to-end visibility.

For more hands-on advice on getting your stock organized, check out these valuable small business inventory management tips.

Combining these strategies doesn’t just deliver a quick win; it builds a foundation for long-term resilience.

Measuring Your Supply Chain Performance

You can’t improve what you don’t measure. Regularly tracking the right metrics helps you spot small issues before they snowball into big, costly problems.

Focus on the key performance indicators (KPIs) that tie directly to your costs and service quality:

- On-Time Delivery Rate: What percentage of your orders arrive exactly when you expect them?

- Forecast Accuracy: How closely did your projected demand match what you actually sold?

- Waste Reduction Percent: How are your FIFO and storage controls impacting the bottom line?

- Inventory Turnover Rate: How quickly are you moving through your entire stock each month?

Set clear, ambitious targets for your team, like a 95% on-time delivery rate or a 10% reduction in food waste.

With a system like Biyo POS, you can monitor these metrics in near real-time, allowing you to turn those insights into immediate, effective action. By starting today, you’re setting the stage for a leaner, more responsive, and more profitable operation.

Leveraging Technology For Supply Chain Mastery

Gone are the days when pen-and-paper logs and scattered spreadsheets could keep pace with a fast-moving kitchen. Technology now acts as the operating system for your restaurant, weaving together sales data, inventory counts, and purchase orders into one cohesive picture.

The right software gives you visibility into what’s happening at every station and control over critical tasks—turning best practices into instinctive habits you rely on day in, day out.

A modern Point of Sale system does far more than ring up orders. When you choose Biyo POS, it becomes your single source of truth, tracking each ingredient as it leaves the line. That real-time stream of data is the foundation you need for a smarter, more forward-thinking supply chain.

The Shift From Manual To Automated Systems

Picture two maps: one hand-drawn with ink, the other on your phone with live traffic updates. The old way—checking clipboards and adding up cells in a spreadsheet—worked, but it was slow, error-prone, and blind to sudden changes. An automated system, on the other hand, shows you the road ahead in real time.

Here’s a simple before-and-after scenario:

Before Technology (The Manual Way):

• Inventory Counts: Managers circle back at week’s end to tally stock by hand, often introducing mistakes when numbers get mixed up.

• Ordering: Decisions rest on hunches and recent rushes, leading to too much produce spoiling or running out of your bestseller.

• Vendor Management: Calls and emails fly back and forth with no single record of who ordered what, when, and at which price.

After Technology (The Automated Way):

• Real-Time Tracking: Every order processed through your Biyo POS subtracts ingredients from your digital inventory, so you see up-to-the-minute stock levels.

• Data-Driven Forecasting: Historical sales pull double duty, generating accurate projections that help you buy just enough—no more, no less.

• Integrated Ordering: Set low-stock alerts that trigger purchase orders, which go straight to suppliers and build an audit trail automatically.

This transition isn’t just about efficiency; it’s about moving from a reactive style of management to a proactive, data-informed approach. You stop putting out fires and start preventing them.

Key Features That Power Your Supply Chain

Modern platforms like Biyo POS bring specific capabilities that reinforce every link in your operation:

• Real-Time Inventory Tracking: Syncs your sales with stock levels so you always know what’s on hand, avoiding surprise shortages.

• Sales Analytics and Reporting: Delivers insights on your top-selling dishes, slow movers, peak hours, and seasonal shifts—essential for precise forecasting.

• Vendor Management Portals: Houses supplier contacts, product lists, pricing history, and delivery records in one place, making communication and performance reviews straightforward.

When these features work in harmony, you gain the clarity and command to implement supply chain strategies confidently—from the moment an order hits the screen to the instant the invoice arrives.

Frequently Asked Questions

It’s completely normal to have questions when you’re trying to get a handle on your restaurant’s supply chain. Below, we’ve answered a few of the most common ones to help you clear those first hurdles and find the right path forward.

What Is The First Step To Improve My Supply Chain?

The best way to start is by taking a hard, honest look at what you’re already doing. Think of it as a check-up for your restaurant’s operations.

Start tracking a few key numbers: What’s your on-time delivery rate from suppliers? How much food are you wasting each week, as a percentage? How often do you run out of a crucial ingredient mid-service? This data gives you a baseline, showing you exactly where the leaks are. Once you know if the problem is a flaky vendor or just bad ordering habits, you can focus on fixing the issue that will make the biggest difference.

How Can A Small Restaurant Benefit From Better SCM?

Even for a small, independent spot, smarter supply chain management is a game-changer. Getting a tighter grip on your ordering and inventory immediately cuts down on food waste—a massive profit killer for any kitchen. It also means you won’t have to 86 your most popular dish on a busy Friday night.

Plus, building solid relationships with a handful of reliable local suppliers can often get you better pricing and fresher ingredients. That’s a real competitive advantage. For a small business, these seemingly minor adjustments add up and hit your bottom line in a big way.

A well-managed supply chain isn’t just a “big chain” strategy. It’s a core business practice that helps independent restaurants protect their profits, reduce chaos, and keep customers happy.

What Technology Is Essential For Getting Started?

For almost any restaurant today, the single most critical tool is a modern Point of Sale (POS) system that has inventory management built right in. This system becomes the command center for your entire supply chain.

A good POS gives you two superpowers right out of the box:

- Real-Time Inventory Tracking: It automatically subtracts ingredients from your stock as you sell dishes. This gives you a live, accurate count of what’s actually on your shelves.

- Sales Data and Analytics: It records every sale, revealing patterns and trends. This helps you forecast demand with real data, so you can stop guessing what you’ll need next week.

Starting with a solid POS system is the foundation for every other improvement you’ll make to your supply chain.

Ready to gain complete control over your inventory and ordering? Biyo POS provides the real-time data and powerful analytics you need to optimize your restaurant supply chain management, cut costs, and boost profitability. Discover how Biyo POS can transform your operations today.