Imagine your inventory is cash, but instead of sitting in a bank account, it's sitting on your shelves. Days of Inventory on Hand (DOH) tells you exactly how long it takes to turn that inventory back into cash.

Think of it this way: if you stopped receiving new stock today, how many days could your business keep making sales before the shelves went bare? That number is your DOH. It's a powerful, real-time indicator of your operational health and efficiency.

What Days of Inventory on Hand Really Tells You

Also known as Days Sales of Inventory (DSI), this metric is more than just a stock-counting exercise. It's a direct reflection of how well your entire supply chain is working, from the moment you purchase goods to the moment a customer buys them.

Understanding your DOH gives you a peek under the hood of your business, helping you spot potential issues before they become serious problems.

The Inventory Balancing Act

Every business owner knows the tightrope walk of inventory management.

On one side, you have too much stock. This ties up precious cash that could be reinvested into marketing, new hires, or expanding your business. It also racks up carrying costs—think storage fees, insurance, and the risk of products becoming damaged, obsolete, or expired.

On the other side, you have too little stock. This leads to frustrating stockouts, which means lost sales and, even worse, lost customer loyalty. Nothing sends a potential customer to your competitor faster than an "out of stock" sign.

Finding that sweet spot with your DOH means you're not just managing stock; you're managing cash flow, customer satisfaction, and financial stability all at once. It’s a sign of a nimble, well-run operation.

A Critical Health Indicator

Keeping a close eye on your DOH offers clear, actionable insights into your business's performance. It’s an early warning system that helps you make smarter strategic moves.

Here’s a quick look at what this single number helps you do:

- Free Up Your Cash: The faster you sell inventory, the quicker you convert it back to cash, giving your business more financial breathing room.

- Gauge Sales Speed: A low DOH usually means products are flying off the shelves, signaling strong market demand.

- Improve Storage and Efficiency: It prevents your backroom from turning into a graveyard for slow-moving products that just take up space and lose value.

DOH is a sibling metric to another important KPI. To see the full picture, you should also understand inventory turnover, which measures how many times your business sells and replaces its entire stock over a specific period.

Mastering both of these turns your inventory from a costly necessity into a true strategic asset.

To make this easier to digest, here's a quick summary of the core concepts.

Days of Inventory on Hand Quick Guide

| Concept | What It Tells You | Potential Implication |

|---|---|---|

| What is DOH? | The average number of days it takes to sell your entire inventory. | It's a snapshot of your inventory efficiency and cash flow cycle. |

| High DOH | You are holding onto inventory for a long time before selling it. | This could signal weak sales, over-ordering, or tied-up capital. |

| Low DOH | You are selling through your inventory very quickly. | This might indicate strong sales but also carries a risk of stockouts. |

Ultimately, the "right" DOH isn't a one-size-fits-all number. It depends heavily on your industry, business model, and the specific products you sell. The goal is to find your unique sweet spot and keep it consistent.

Calculating Your Days of Inventory on Hand Step by Step

Turning the concept of DOH into a real, hard number is probably easier than you think. You don't need fancy software to get a starting point; all it takes is a straightforward formula and a quick look at your business's financial statements.

At its core, the calculation is all about the relationship between how much inventory you're holding and how fast you're actually selling it. This gives you that clean, clear timeline in days.

The DOH Formula Unpacked

The magic formula for Days of Inventory on Hand looks like this:

DOH = (Average Inventory / Cost of Goods Sold) × Number of Days in Period

This simple equation tells you how many days it would take to completely sell through your current inventory, assuming your sales pace stays consistent. When you're looking at a full year, you'll use 365 days. For a quarterly review, just plug in 90 days.

So, to get started, you'll need to pull three key pieces of information:

- Average Inventory

- Cost of Goods Sold (COGS)

- The Time Period (in days)

Let's walk through finding the first two.

Step 1: Find Your Average Inventory

Because your stock levels are always in flux—going up with new orders and down with every sale—using a single day's number won't give you an accurate read. Averaging it out smooths out those peaks and valleys.

To get this number, just grab your balance sheet.

Average Inventory = (Beginning Inventory + Ending Inventory) / 2

For instance, say you started the quarter with $20,000 worth of inventory and ended it with $30,000. Your average inventory for that period is ($20,000 + $30,000) / 2 = $25,000. Simple as that.

Step 2: Determine Your Cost of Goods Sold

Next up is your Cost of Goods Sold (COGS). You can find this figure on your income statement for the same time frame. COGS is simply the direct cost tied to producing the products you sold.

This number is what connects your inventory value to your actual sales activity, making it a crucial part of the puzzle. If you want to get a better handle on this metric, our guide on how to master Cost of Goods Sold and boost profit margins is a great resource.

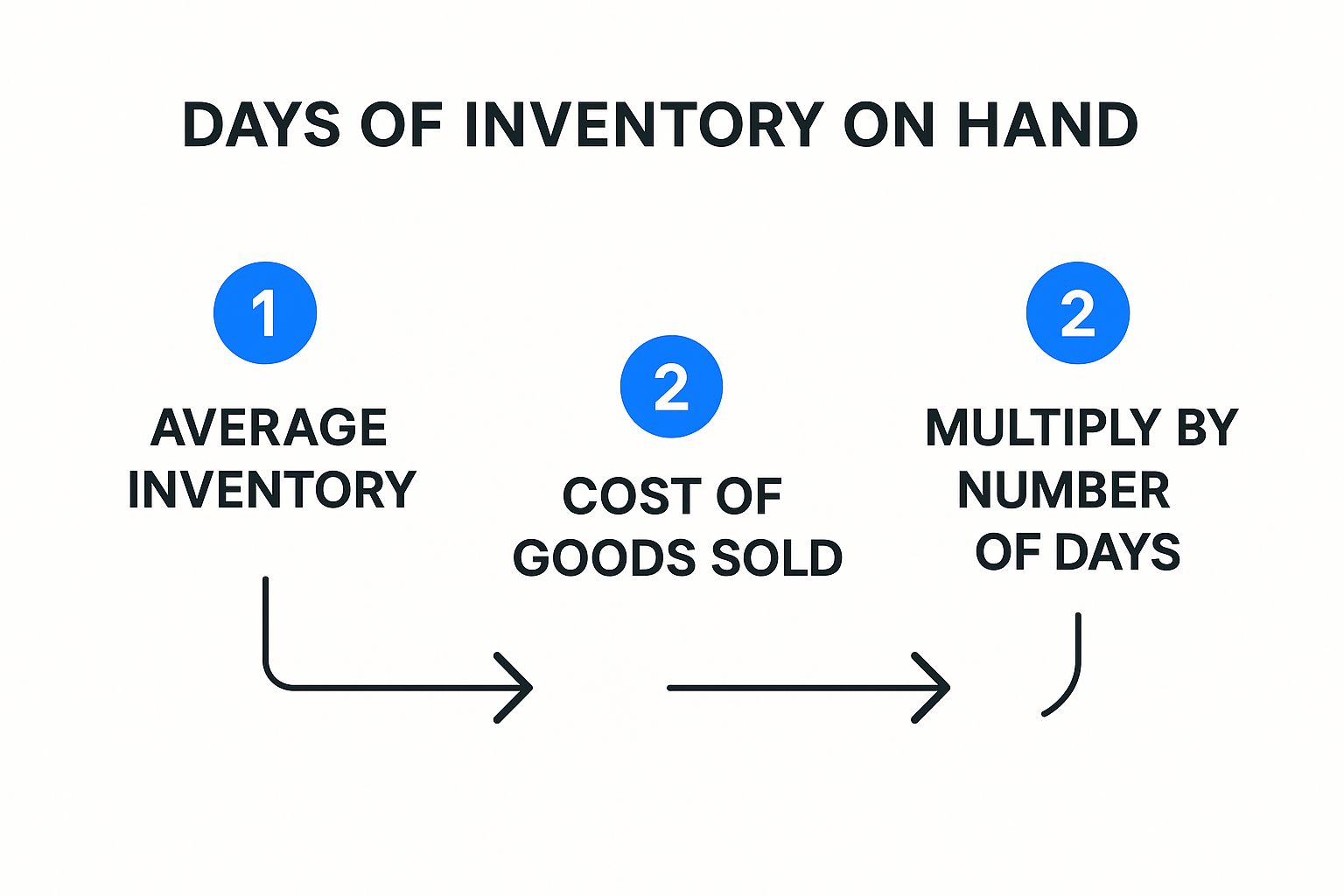

This infographic breaks down the simple three-step process.

As you can see, once you have your average inventory and COGS, you're just one quick calculation away from the answer.

Step 3: Put It All Together

Now for the final step. Let's plug the numbers from our example into the formula:

- Average Inventory: $25,000

- Quarterly COGS: $50,000

- Time Period: 90 days

DOH = ($25,000 / $50,000) × 90 days = 45 days

What does this tell us? It means that, on average, it takes this business 45 days to sell through its entire stock.

Getting comfortable with this calculation is also a key first step in mastering the Cash Conversion Cycle, which measures how long it takes for the money you invest in your inventory to come back to you as cash. It's a simple number that unlocks a much deeper understanding of your business's financial health.

So, What's a Good DOH Number? (And Why That's the Wrong Question)

You’ve done the math and now you have your Days of Inventory on Hand (DOH) number staring back at you. Now what? The biggest trap businesses fall into is trying to find a single, universal "good" DOH. But here’s the reality: that number doesn't exist.

Figuring out what your DOH means is less about hitting a magic number and more about understanding what's right for your business. A high DOH isn't automatically a red flag, and a low one isn't always a sign of genius. It all comes down to context.

Look to Your Industry for Clues

The ideal DOH can swing wildly from one industry to the next. Think about it: a local grocery store selling fresh bananas has a completely different inventory reality than a boutique selling custom diamond rings.

-

Fast-Moving Goods: For that grocer, a DOH of just 2-3 days is a sign of success. They need to sell produce before it spoils. A high DOH here would be a financial disaster, leading to massive waste. The same goes for fast-fashion retailers who need to clear out inventory in weeks to stay on trend.

-

Slow-Moving Goods: On the other hand, the jeweler might be perfectly happy with a DOH of 180 days or even longer. Their inventory is high-value, it doesn't expire, and customers expect a wide selection. A super-low DOH would probably mean they don't have enough options to make a sale.

Your first move should be to stop comparing your business to completely different industries. Find out what the benchmarks are for your specific niche to get a real sense of where you stand.

A high DOH in an industry with a slow sales cycle might be totally normal. That same number in a fast-paced retail environment could mean you're in deep trouble.

Finding Your Strategic Sweet Spot

Even within your industry, the perfect DOH depends on your unique business strategy. Are you focused on high volume with thin margins, or do you sell fewer items at a much higher price point? Your answer helps shape your inventory goals.

The real goal is to strike a balance. You need enough product on hand to keep customers happy and avoid stockouts, but not so much that all your cash is tied up in boxes sitting in a back room.

Nailing this balance is fundamental to your financial health. DOH is a fantastic metric for inventory, but it's just one piece of the puzzle. For a broader view of your business's financial stability, you might also look into calculating your Debt Service Coverage Ratio (DSCR), another key performance indicator.

Ultimately, your DOH isn't a static grade on a report card; it’s a living number. The real insights come from tracking it over time. How does this quarter compare to the same one last year? If it’s creeping up, are sales slowing down or did you overbuy? If it’s dropping, is your new marketing campaign crushing it, or are you getting dangerously close to running out of stock? This kind of ongoing analysis is what turns a simple metric into a powerful strategic tool.

Real World Examples of DOH in Action

The formula for days of inventory on hand is one piece of the puzzle. The real magic happens when you see how the biggest players in the game use it to their advantage. This isn't just a number tucked away in a report; it's a core component of how some of the world's most successful companies operate.

By taking a look at how different industry leaders manage their DOH, you can pick up some powerful ideas for your own business. They don't just manage inventory; they use it as a strategic tool to get ahead. Optimizing DOH isn't simply about saving money—it's about building a smarter, faster, and more profitable business from the inside out.

The Retail Titans Walmart and Amazon

When you think of retail giants, Walmart and Amazon immediately come to mind. They're both massive, but their DOH strategies couldn't be more different, and it all comes down to their business models.

Walmart is the undisputed champion of logistical efficiency. Its entire operation is built on selling huge volumes of products with very slim profit margins. To make that work, they aim for an extremely low DOH. They’ve perfected their supply chain to get products onto the shelves right when they're needed, which keeps their holding costs down and their cash flowing freely. In the cutthroat world of groceries and retail, that's a massive competitive edge.

Amazon is playing a different game. Its DOH is generally higher than Walmart's, but that’s by design. Amazon's promise is to be the "everything store" with lightning-fast shipping. To deliver on that, they have to keep an incredible amount of varied stock ready to go in warehouses all over the world. For them, DOH is a careful balancing act between having everything a customer could want and running an efficient operation.

Global leaders have turned the Days of Inventory on Hand metric into a strategic weapon for supply chain dominance. From retail to manufacturing, these examples show that mastering DOH is key to leading the market. For more on inventory KPIs, you can find great insights online.

The Fast Fashion and Lean Manufacturing Pioneers

If you want to see the power of a super-low DOH, look no further than Zara and Toyota. These two companies completely changed their industries by turning traditional inventory management on its head.

-

Zara's Fast-Fashion Model: The fashion world was rocked by Zara's approach. They keep their DOH incredibly low by producing clothes in small batches and using a nimble supply chain to rush new designs to stores in a matter of weeks. This means they rarely get stuck with out-of-style clothes that need to be heavily discounted, which protects their profits and keeps customers coming back for what's new.

-

Toyota's Just-in-Time System: In the manufacturing world, Toyota is legendary for its just-in-time (JIT) system. The idea is simple but revolutionary: parts are produced only when they're needed for the next step in the assembly line. This slashes their DOH, reduces waste, and makes the whole production process far more efficient.

These examples make it crystal clear: managing your days of inventory on hand is a critical business decision, not just a bookkeeping chore. Your DOH number says a lot about your strategy, whether your priority is speed, variety, or pure cost savings.

Common DOH Pitfalls and How to Avoid Them

Figuring out your days of inventory on hand (DOH) is a solid start, but the real magic happens when you know how to read the story it’s telling. It’s an incredibly useful metric, but it's easy to fall into a few common traps that can lead to costly inventory mistakes.

The biggest mistake is looking at your DOH in a vacuum. A single number, without any context, is pretty much useless. For example, a rising DOH could mean sales are slowing down, which is bad. Or, it could mean you're intentionally stocking up for a big holiday rush, which is smart. The number is just noise until you layer in other factors like sales velocity, profit margins, and recent marketing campaigns.

Ignoring Seasonality and Averages

Relying on a single, year-round average for your DOH can hide some serious problems. Most businesses have natural peaks and valleys, and seasonality plays a huge role in what a "good" DOH looks like at any given time.

A toy store, for instance, will see its DOH naturally climb in the fourth quarter and then drop like a rock in January. Comparing Q4 to Q1 is like comparing apples and oranges. A much smarter move is to compare this year’s Q4 to last year’s Q4 to see if you’re actually improving.

A sudden change in your DOH isn't just a data point; it's a signal. It might be telling you about a hiccup in your supply chain, a new trend your customers are jumping on, or that your new product is a hit. The real strategy begins when you start asking "why" that number changed.

Overlooking External Factors

It's also easy to get tunnel vision and forget that outside forces can mess with your inventory levels. A sudden supply chain disruption can make your DOH look artificially low simply because you can't get new stock in. You might feel efficient right before you run out of everything.

Likewise, what if a competitor runs a massive sale? It could temporarily crater your own sales and send your DOH soaring. Smart business owners are always looking beyond their own four walls to see how the market is shifting.

You can see this play out with major retailers. Their DOH figures often reflect these external pressures. For example, Target’s DOH once jumped by over 11% in a single year, going from 61.67 to 68.69 days, which was likely a direct response to a sales slowdown. You can find more data on retailer DOH trends to see just how much these numbers can fluctuate.

By keeping these common pitfalls in mind, you can turn your DOH from a simple measurement into a genuinely powerful tool for planning your next move.

How to Get Your Days of Inventory Under Control

Knowing your days of inventory on hand (DOH) is one thing, but actually improving it is where the magic happens. A lower DOH isn't just a vanity metric; it means you've unlocked cash, cut down on waste, and made your entire business more responsive.

The good news? You don't need to reinvent the wheel to see a difference. The right mix of smarter forecasting, modern tech, better supplier relationships, and strategic sales can turn your inventory from a liability into a genuine asset.

Sharpen Your Demand Forecasting

The quickest way to a better DOH is to get really good at predicting what your customers will want. When you can anticipate demand, you stop tying up cash in products that just sit there, gathering dust.

Stop guessing and start digging into your sales data to find patterns. Look at past sales reports to understand seasonal ebbs and flows and see which products consistently fly off the shelves. Learning a few solid inventory forecasting techniques can help you build a system based on facts, not feelings.

Let Technology Do the Heavy Lifting

Are you still tracking everything on a spreadsheet? That’s a recipe for mistakes and wasted time. A modern POS system with built-in inventory management gives you a live, accurate picture of your stock at all times.

This kind of system allows you to:

- Set automatic reorder points: You can restock popular items right before they run out, which helps prevent disappointing customers without over-ordering.

- Spot your slow-movers: Easily flag the products that aren't selling so you can run a promotion, create a bundle, or decide to stop carrying them altogether.

- Get real-time data: Know precisely what you have in stock at any given moment, empowering you to make much smarter buying decisions on the fly.

A healthy DOH is more than an operational win—it’s a sign of financial strength. It shows potential investors and lenders that you know how to manage your assets well, painting a picture of a stable and well-run business.

Work Smarter with Your Suppliers

Your suppliers are more than just vendors; they're your partners in this process. A strong, open relationship can lead to better terms that have a direct, positive impact on your DOH.

Talk to them about placing more frequent, smaller orders instead of one massive bulk purchase. Sure, the per-unit cost might be a tiny bit higher, but it dramatically reduces how much cash you have locked up in stock. Pushing for shorter lead times also gives you the agility to react quickly when customer demand suddenly shifts.

Common Questions About Days of Inventory on Hand

Once you start using days of inventory on hand in your day-to-day operations, a few practical questions almost always pop up. Let's tackle some of the most common ones so you can apply this metric with confidence.

Can My Days of Inventory on Hand Be Too Low?

Yes, absolutely. It's a classic case of "too much of a good thing." While a low DOH is generally a sign of efficiency, a number that’s too low is a major red flag. It often means you're understocked.

When you're understocked, you risk running out of products people want to buy. That leads directly to stockouts, lost sales, and frustrated customers who might just decide to shop elsewhere next time. The goal isn’t to hit rock bottom, but to find that sweet spot—the perfect balance between lean inventory and enough stock to keep customers happy.

How Often Should I Be Calculating My DOH?

There's no single right answer here; it really depends on the pace of your business.

If you’re in a fast-moving industry like retail or food service, you’ll want to calculate DOH frequently—think monthly, or even weekly. This keeps you agile and able to react to quick changes in customer demand. On the other hand, for businesses dealing with slower-moving, high-value items (like an auto dealership or a furniture store), a quarterly calculation is usually plenty to keep a finger on the pulse.

The most important part is just being consistent. Calculating your days of inventory on hand on a regular schedule is what lets you spot trends, track your progress, and turn this number from a simple metric into a powerful planning tool.

How Does Seasonality Affect My DOH Calculation?

Seasonality can throw a real wrench in your calculations if you're not careful. Think about it: a toy store's inventory is going to balloon right before the holidays, which will naturally cause a huge spike in their days of inventory on hand.

To get a clear picture of your performance, you can't compare apples to oranges. A slow summer quarter will always look different from a busy holiday quarter. Instead, focus on year-over-year comparisons (like Q4 this year versus Q4 last year). Another great technique is to use a rolling 12-month average for your data, which helps smooth out those seasonal peaks and valleys for a more stable, year-round view of your inventory health.

Ready to take control of your inventory with a system built for clarity? Biyo POS offers real-time inventory management that helps you find your optimal stock levels, prevent stockouts, and free up cash flow. See how it works by visiting Biyo POS and starting your free trial today.