Par level inventory is one of the simplest and most effective ways to figure out how much stock you need to have on hand at any given time. Think of it like a thermostat for your inventory—it automatically tells you when it’s time to reorder. This approach keeps you ahead of the game, ensuring you can always meet customer demand between deliveries without sinking your cash into a mountain of excess stock.

Understanding Par Level Inventory

Imagine a "full" line marked on the shelf for every single product you sell. That’s your par level. The moment your stock count dips below that pre-set number, it's the trigger to place a new order. The goal is simple: replenish your inventory right back up to that par level, creating a smooth and predictable stock management cycle.

This system is all about shifting from reactive, last-minute ordering to a proactive, data-driven process. Instead of guessing when to buy more, you’re setting a clear threshold that takes all the uncertainty out of the equation.

The Core Benefits Of Using Par Levels

For any business that holds stock, from a busy café to an expanding retail store, getting a handle on par levels can be a total game-changer. It creates a solid foundation for more efficient operations and healthier profits by helping you find that perfect inventory balance.

The main advantages really boil down to this:

- Preventing Costly Stockouts: You sidestep the nightmare of telling a customer, "Sorry, we're out of that." This keeps sales flowing and customers happy.

- Reducing Overstock and Waste: It stops you from tying up precious cash in products that just sit there, collecting dust and taking up space.

- Simplifying The Ordering Process: It establishes a straightforward, repeatable system for reordering that anyone on your team can easily follow.

A Proven Strategy For Success

This concept, also known as Periodic Automatic Replenishment (PAR), isn't new. It's been a go-to strategy in the hospitality and food service industries for decades for a good reason. One study revealed that over 65% of mid-to-large-sized restaurants using a PAR level system saw an average 18% reduction in food waste and a 22% improvement in inventory turnover.

By defining the ideal quantity for each item, par levels remove the guesswork from inventory control. This allows you to maintain optimal stock levels, ensuring you can consistently meet customer demand without the financial strain of carrying unnecessary surplus.

To get a better sense of how this proactive approach stacks up against more traditional methods, here's a quick comparison.

Par Level Inventory At A Glance

| Aspect | Par Level Inventory (Proactive) | Traditional Ordering (Reactive) |

|---|---|---|

| Trigger | Stock drops below a pre-set minimum. | A manager notices stock is low or gone. |

| Timing | Consistent and scheduled. | Irregular and often last-minute. |

| Decision-Making | Based on data (sales velocity, lead time). | Based on guesswork or gut feeling. |

| Risk | Low risk of stockouts or overstock. | High risk of stockouts and excess inventory. |

| Efficiency | Highly efficient and easy to delegate. | Time-consuming and reliant on key staff. |

As you can see, implementing par levels brings a much-needed structure to your reordering process.

Understanding par levels is a critical first step toward mastering broader small business inventory management strategies, helping you cut costs and boost efficiency across the board.

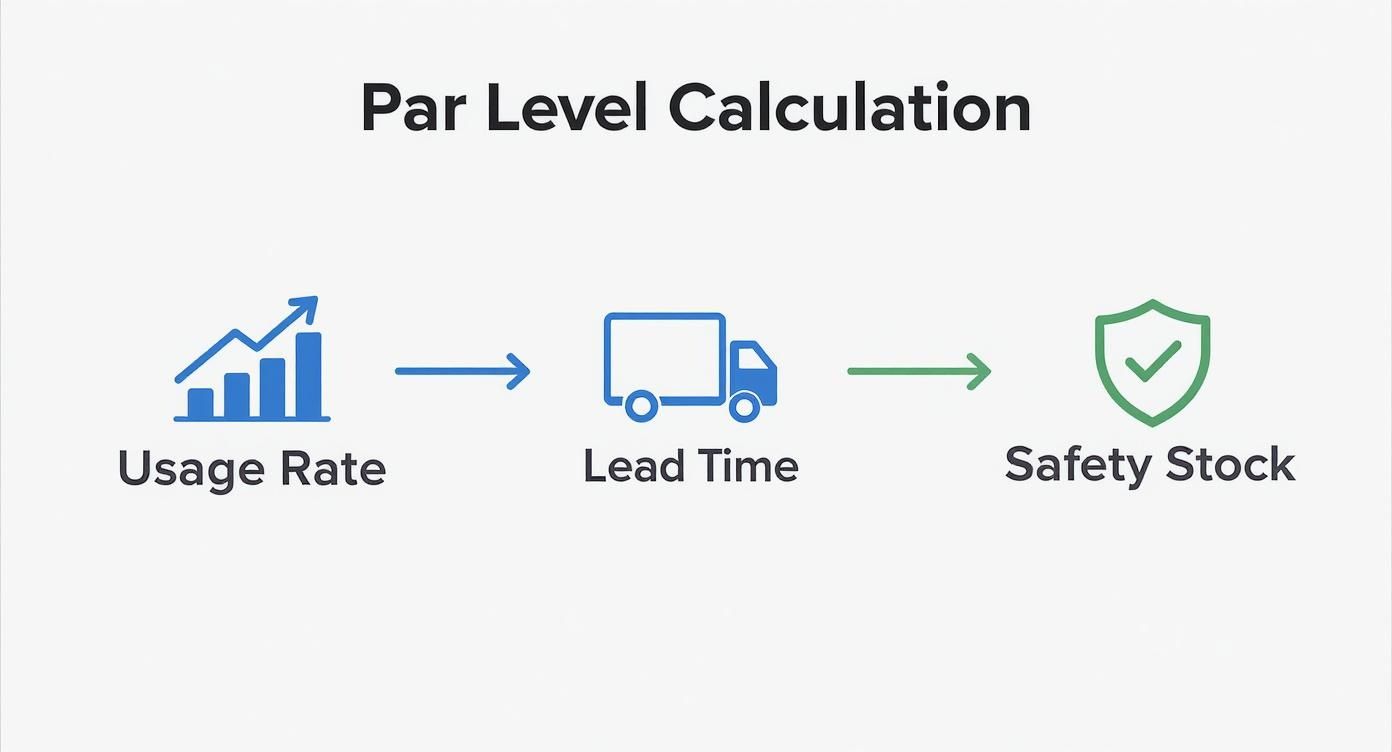

The Three Pillars of Par Level Calculation

Figuring out your par levels isn't about getting lost in complex spreadsheets. It’s actually based on a straightforward formula built on three business realities you deal with every day. Once you get a handle on these three components, you can set a reliable par level for every single item you stock, one that truly matches the unique rhythm of your business.

These three pillars—usage, lead time, and a safety buffer—work together to give you a complete picture of your inventory needs. Let's break down exactly what they are and how they fit together.

Understanding Your Usage Rate

First up, and most importantly, is your usage rate. This is simply the answer to the question: "How much of this item do I sell in a typical day or week?" Are you going through 10 bottles of cold brew a day or 100? This number is the heartbeat of your inventory, giving you a direct line into customer demand.

Without a solid grasp of your usage rate, any par level you set is just a shot in the dark. The best way to find it is to look at your sales data over a specific period, like a week or a month, to calculate a dependable average. A modern POS can be a huge help here, instantly showing you which products are flying off the shelves and need the most attention.

Factoring in Supplier Lead Time

Next, you have to account for lead time. This isn't just about shipping; it's the total time that passes from the moment you place an order with your supplier to the moment that new stock is on your shelves, ready to be sold. It includes everything from their processing time to your own internal receiving steps.

For example, if it takes your coffee bean supplier four days to get a new batch to you after you've placed the order, your lead time is four days. This number is critical because it represents the window where you're most vulnerable to running out of stock while you wait for that replenishment to arrive.

A classic mistake is underestimating lead time. It’s easy to do, but it can leave you with empty shelves even when you thought you ordered in plenty of time. Always base your lead time on real-world delivery history, not just what a supplier estimates.

The Importance of Safety Stock

The final pillar is your safety stock. Think of this as your inventory insurance policy—it’s that small, extra buffer you keep on hand just in case things don't go as planned. It’s there to protect you from the unexpected.

What if a sudden heatwave triples your iced tea sales? Or what if your main supplier has a delay? Your safety stock is what prevents a minor hiccup from turning into a full-blown stockout crisis. How much you need depends on how vital the item is and how reliable its supply chain is. Nailing this balance is a core skill in inventory management, and it goes hand-in-hand with learning different inventory forecasting techniques to better predict what's coming.

How to Calculate Your Par Levels Step by Step

Alright, now that we’ve covered the three pillars of a solid par level, it's time to roll up our sleeves and put them to work. Calculating your ideal stock levels isn't about guesswork or gut feelings. It's about using a simple but powerful formula that turns your own operational data into real, actionable inventory targets.

The standard formula for setting a par level looks like this:

Par Level = (Usage Per Day × Lead Time in Days) + Safety Stock

This formula gives you a clear, data-driven starting point. Let’s walk through it with a real-world example to see exactly how it works in practice.

The graphic below shows how each piece of the puzzle—usage, lead time, and your safety cushion—comes together to give you that final number.

As you can see, it’s all about combining what you sell daily, how long it takes your suppliers to restock you, and a smart buffer to create an inventory target you can rely on.

A Practical Example: A Busy Restaurant

Let's imagine you run a popular Italian spot, and your "Spicy Shrimp Arrabiata" is flying out of the kitchen every night. The key ingredient you constantly need to monitor is the frozen shrimp. Your goal is to figure out the perfect par level for your 2-pound bags of shrimp.

Here’s how you’d find each variable for the formula:

-

Calculate Your Daily Usage: You pop open your Biyo POS sales data from the last month and see you went through an average of 12 bags of shrimp per week. That breaks down to about 1.7 bags per day (12 bags ÷ 7 days). To keep the math simple, let's round that up to an even 2 bags per day.

-

Determine Your Lead Time: Your seafood supplier delivers every Tuesday and Friday. If you place an order on Monday morning, it arrives the next day. But what if you get slammed and need to order on Tuesday afternoon? That order won't show up until Friday. To play it safe, your realistic lead time is 3 days.

-

Set Your Safety Stock: Shrimp is absolutely essential for a signature dish, so running out is not an option. You decide on a safety stock of 6 bags—enough to cover three full days of service if there's a surprise rush or a delivery truck gets delayed.

Putting the Par Level Formula Together

Now, you just plug those numbers right into the formula:

Par Level = (2 bags per day × 3 days lead time) + 6 bags safety stock

The math is straightforward:

Par Level = 6 + 6 = 12 bags

And there you have it. Your par level for frozen shrimp is 12 bags. This means that whenever a new delivery arrives, you want to see exactly 12 bags sitting in your freezer. So, if your team does a quick count and finds only 7 bags left, you know instantly you need to order 5 more to get back up to par. This whole process gets a lot easier with the right tools, and you can see what's out there in our guide to the top food inventory templates for restaurant management.

The power of this method isn't limited to restaurants. In the pharmaceutical world, for instance, hospitals that implement PAR systems have been shown to reduce medication stockouts by up to 30%, which has a massive impact on patient care. The principles are the same, whether you're stocking shrimp or life-saving drugs.

Putting Your Par Levels to Work Every Day

Knowing your par levels is one thing, but making them a part of your daily rhythm is where the real magic happens. The goal is to move from a formula on a spreadsheet to a smooth, repeatable process your team can follow without thinking twice. This isn't about adding more work; it's about making inventory checks and reordering a predictable, stress-free part of the routine.

The simplest and most effective tool for this is the par sheet. Forget anything complicated—this can be a clipboard with a checklist, a laminated sheet you can reuse, or a basic spreadsheet on a tablet. It just needs to list your key items and their par levels, giving your team an instant visual of what "full" looks like.

Of course, modern systems like Biyo POS give you a digital version of this. You get a live dashboard showing what you have, what you should have (your par level), and what needs to be ordered, all in one place. It makes spotting gaps as easy as a quick glance.

Creating a Reordering System Anyone Can Follow

With your par sheet in hand, the next step is building a reordering process that's so simple even a brand-new hire could manage it. Consistency beats complexity every time.

A solid system really boils down to three simple steps:

- Set a Time for Stock Counts: Make it a habit. Check your fast-moving items daily and your slower ones weekly. The key is to pick a time and stick to it.

- Define a Clear "Next Step": When an item is below its par level, what happens? The process should be obvious—fill out the order form, click a button in your POS, or let the manager know. No ambiguity.

- Check and Receive Orders: When a delivery arrives, someone needs to confirm you got what you paid for. They check it against the order slip and, most importantly, update your inventory counts immediately.

Picture a bar manager after a hectic Saturday night. With a par sheet on a clipboard, they can walk the stockroom and see they have 7 bottles of the house vodka left, but their par is 12. They instantly know to order 5 more. No math, no memory, just a clear action.

Making Par Levels Part of Your Culture

For this system to stick, it needs to be woven into the fabric of your daily operations. That means giving your team the right tools and, crucially, explaining the why behind it all.

When your staff understands that keeping items at par prevents the frustration of running out mid-service, they'll buy into the process. It's not just about counting bottles; it's about making everyone's job easier and keeping customers happy.

For any business serious about inventory, this is just one piece of the puzzle. A complete restaurant inventory management system can do a lot of the heavy lifting for you, from tracking sales data in real-time to automatically flagging items that dip below par. When you combine smart technology with a simple, human-focused process, you build an inventory system that actually works—one that protects your profits day in and day out.

When and How to Adjust Your Par Levels

Getting your par levels set is a huge first step, but the work doesn't stop there. Think of your par levels less like a fixed rule and more like a living guide that has to evolve with the natural rhythm of your business. A number that worked perfectly last quarter could easily cause stockouts or overstock next month if you don't keep an eye on it.

To keep your inventory strategy sharp, you need to know when to step in and make adjustments. This isn't about micromanaging; it's about staying nimble and making sure your stock is always aligned with what your customers are actually buying.

Key Triggers for Par Level Adjustments

Certain events are clear signals that your old numbers might be out of date. Paying attention to these triggers helps you get ahead of inventory headaches before they even start.

Here are a few of the most common signs it's time for a review:

- Seasonality: This is the most obvious one. A coffee shop will burn through cold brew in July but sell way more hot chocolate in December. Your par levels need to reflect these predictable swings.

- Upcoming Promotions: Got a big sale or a "buy one, get one" deal on the calendar? The demand for that item is about to jump, and you’ll need to raise its par level temporarily to keep up.

- Menu or Product Changes: When you add a new best-seller to the menu or decide to drop an unpopular item, the usage rates for all the related ingredients will change instantly. Every update to your offerings should trigger an update to your par levels.

- Supplier Reliability Issues: If your go-to supplier suddenly starts having shipping delays, your lead time just got longer. You'll likely need to bump up your par levels or safety stock to build a bigger buffer until things get back to normal.

The most successful businesses treat their par levels not as static rules but as dynamic guidelines. Regularly reviewing and fine-tuning these numbers based on fresh data is what separates adequate inventory management from excellent inventory management.

Establishing a Rhythm for Review

So, how do you keep this from becoming a chaotic, reactive process? You build a routine. For most businesses, setting aside time for a monthly or quarterly review is the perfect starting point. This gives you a consistent opportunity to dive into recent sales data from your POS, spot new trends, and make adjustments based on facts, not guesswork.

This simple discipline pays off, big time. In the retail world, an impressive 70% of businesses using par levels reported an average 20% reduction in overstocking and a 25% decrease in stockouts. A European supermarket chain even managed a 30% reduction in food waste just by applying this strategy to its perishable goods.

By making regular adjustments a core part of your operations, you can see similar results and ensure your inventory is always an asset, not a liability.

When To Adjust Your Par Levels

Recognizing the right time to adjust your par levels is crucial for maintaining an efficient and profitable inventory system. The table below outlines common business scenarios that should prompt you to review and possibly change your established par levels.

| Trigger Event | Reason for Adjustment | Example Action |

|---|---|---|

| New Marketing Campaign | A successful campaign can unexpectedly increase demand for a specific product. | For a "Taco Tuesday" promotion, increase the par level for ground beef, tortillas, and salsa for Monday deliveries. |

| Local Events or Holidays | Festivals, holidays, or major local events can cause temporary spikes in customer traffic and sales. | A coffee shop near a parade route should raise par levels for coffee beans, milk, and cups the week of the event. |

| Changes in Customer Behavior | New trends (like a popular diet) can shift demand away from some items and toward others. | If a gluten-free trend gains traction, lower the par for regular flour and increase it for almond or coconut flour. |

| Supplier Price Changes | A significant price increase from a supplier might make you want to stock less of an item to manage costs. | If the cost of avocados doubles, you might lower your par level to reduce spoilage risk on a high-cost ingredient. |

| New Competition Nearby | A new competitor opening down the street could impact your sales volume, either up or down. | After a new boutique opens nearby, monitor sales for a month and adjust par levels for key products accordingly. |

By staying vigilant and responding to these triggers, you can keep your par levels optimized. This proactive approach ensures you're always prepared, minimizing waste while maximizing sales opportunities.

Common Par Level Mistakes and How to Avoid Them

Switching to a par level system is a game-changer, but a few common slip-ups can easily derail your efforts. By getting ahead of these issues, you can make sure your inventory management starts paying dividends right away, turning your stockroom from a headache into a well-oiled machine.

The single biggest mistake? Setting par levels based on a hunch instead of solid data. Guessing how much stock you need is just a shot in the dark, and it’s no better than the reactive ordering you're trying to escape. This almost always leads to one of two expensive problems: cash tied up in overstocked shelves or frustrating, sale-killing stockouts.

The fix is simple: always base your par levels on actual sales data. Your POS reports are a goldmine of information. Dig in, find out what your real usage rates are, and let the numbers guide you. They provide the rock-solid foundation you need for an inventory system that actually works.

Ignoring Your Supply Chain Reality

Another classic blunder is forgetting to factor in how long it really takes for an order to arrive. It's easy to plug in the two-day shipping a supplier promises, but we all know reality can be a bit more unpredictable. Delays are a part of life, and if you don't build a buffer for them, you’re leaving yourself wide open to empty shelves.

Start tracking your actual delivery times over several orders to find a true average lead time. If a supplier is constantly late, you have a choice: adjust your par levels to account for it or start looking for a partner you can count on. This simple step is your best defense against unexpected shortages.

The whole point of a par level system is to build predictability into your operations. Ignoring real-world curveballs like inconsistent suppliers or team oversight just brings back the same chaos you were trying to eliminate.

A third major pitfall is not training your team properly. You can have the most brilliant par level formula in the world, but it means nothing if your staff doesn't understand their role. Without clear guidelines, stock counts get sloppy and reordering turns into a free-for-all.

Forgetting Par Levels Are Dynamic

Finally, so many businesses fall into the "set it and forget it" trap. The par level that was perfect for you in January will absolutely sink you during the holiday rush. Your inventory needs change constantly, and your par levels have to change with them.

To stay on top of it, schedule regular par level check-ins. You should be reviewing them at least quarterly, and always before a big seasonal shift or a major promotion.

- Review Sales Data: Keep an eye on your POS trends. Is an item suddenly flying off the shelves or gathering dust?

- Talk to Your Team: The people on the floor are your eyes and ears. They often spot shifts in customer demand long before the data does.

- Analyze Waste/Spoilage Reports: If you're suddenly throwing more of something away, it’s a big red flag that your par level is too high.

Treating your par levels as a living, breathing part of your business is the key. By sidestepping these common mistakes, you'll keep your inventory perfectly in sync with what your business actually needs.

Got Questions About Par Levels? We've Got Answers

Even the best plans run into questions once you start putting them into practice. As you get your par level system up and running, a few things might pop up. Here are some quick, clear answers to the most common queries we hear.

How Often Should I Check My Par Levels?

The honest answer? It completely depends on how fast the item sells.

For your fastest-moving products—think fresh ingredients in a cafe or your daily best-sellers—you'll want to do a daily check. For slower-moving items, a weekly count will probably do the trick.

The key isn't a one-size-fits-all schedule; it's establishing a consistent rhythm. That consistency is what ensures you never miss the reorder window for your most important stock.

What's the Difference Between a Par Level and a Reorder Point?

This is a great question because they sound similar but do two different jobs. Think of them as a tag team.

- Par Level: This is your goal. It’s the ideal amount of an item you want sitting on your shelf right after a new delivery lands. It's what "full" looks like.

- Reorder Point: This is your trigger. It’s the minimum stock level that sends up a flare, signaling it's time to place a new order.

To put it simply, your reorder point tells you when to order. Your par level tells you how much to order to get back to your sweet spot.

Is Par Level Inventory a Good Fit for a Small Business?

Absolutely. In fact, it might be one of the smartest inventory strategies a small business can use. You don't need a massive team or complicated software to get started; the system works just as well with a simple spreadsheet or even a checklist.

For any small business, cash flow is everything. A par level system is a direct way to protect your money. It stops you from tying up precious cash in dusty, excess inventory while also making sure you don't lose out on sales because of an easily avoidable stockout. It gives you a simple, powerful framework for smarter inventory control.

Ready to stop guessing and start managing your inventory with real data? Biyo POS has powerful, built-in tools that make setting and tracking your par levels almost effortless. Get started with a free trial today!